A gantry crane is a type of overhead crane with a single or double girder configuration supported by freestanding legs that move on wheels or along a track or rail system. Gantry cranes are usually considered when there is a reason not to incorporate an overhead runway system.

These are typically used for an outdoor application or below an existing overhead bridge crane system. Unlike a bridge crane, a gantry crane does not need to be tied into a building’s support structure—eliminating the need for permanent runway beams and support columns. In some cases, this can result in a significant reduction in material costs and can be a more cost-effective solution compared to a similarly specified bridge crane.

Larger gantry systems may run on a rail or track embedded in the ground, typically in a straight line in a dedicated work area. Smaller portable gantry systems run on castors or wheels and can be moved about a facility for maintenance or light fabrication work

These are typically used for an outdoor application or below an existing overhead bridge crane system. Unlike a bridge crane, a gantry crane does not need to be tied into a building’s support structure—eliminating the need for permanent runway beams and support columns. In some cases, this can result in a significant reduction in material costs and can be a more cost-effective solution compared to a similarly specified bridge crane.

Larger gantry systems may run on a rail or track embedded in the ground, typically in a straight line in a dedicated work area. Smaller portable gantry systems run on castors or wheels and can be moved about a facility for maintenance or light fabrication work

Different Types Of Gantry Crane

A) Portable Gantry Crane Systems

Convenient gantry cranes are more modest lighter-obligation gantry frameworks that sudden spike in demand for casters or elastic wheels. These wheels permit the client to move it all through an office to deal with different materials or burdens. At the point when they're vacant and not under burden, they can be moved or put away anyplace all through a shop or into various work cells to offer more prominent space-saving and floor space adaptability.

Convenient gantry cranes are more modest lighter-obligation gantry frameworks that sudden spike in demand for casters or elastic wheels. These wheels permit the client to move it all through an office to deal with different materials or burdens. At the point when they're vacant and not under burden, they can be moved or put away anyplace all through a shop or into various work cells to offer more prominent space-saving and floor space adaptability.

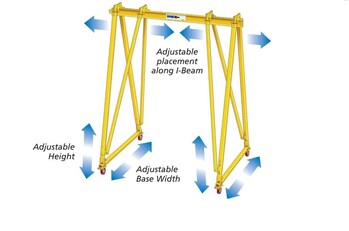

B) Adjustable Gantry Cranes

Adjustable gantry cranes can be designed with variable height and span design. Adjustability allows the end user to change the height of the beams—offering more flexibility when transporting a gantry system in and out of a facility or through different areas of a shop.

Adjustable gantry cranes can be designed with variable height and span design. Adjustability allows the end user to change the height of the beams—offering more flexibility when transporting a gantry system in and out of a facility or through different areas of a shop.

Uses Of Gantry Crane

A) Full gantry or semi-gantry cranes are ordinarily utilized for hefty creation applications, or in some kind of open air yard—rail yards, transportation and holder yards, steel yards, and scrap yards.

B) They're additionally famous for concrete and precast applications for territories where they're framing and restoring chunk concrete. Their plan permits them to be utilized outside and furthermore permits forklift trucks and other mechanized traffic to work and cross through under.

C)Ordinarily, compact gantry cranes are utilized to lift and hold something set up while it's being chipped away at, manufactured, or collected. The heap isn't really being traveled through the office, however the gantry itself can be moved around to chip away at various parts or gear.

D)Versatile gantry frameworks can likewise offer more adaptability than a jib crane or workstation crane. A jib crane ordinarily must be introduced onto a poured solid establishment and whenever it's introduced—it's basically perpetual. A more modest convenient gantry crane can play out a similar sort of work as a jib crane, however can be moved about your office as your business develops and you start enhancing and spreading out stockroom space.

For more information contact us on [email protected] or call us on +971 43336278

B) They're additionally famous for concrete and precast applications for territories where they're framing and restoring chunk concrete. Their plan permits them to be utilized outside and furthermore permits forklift trucks and other mechanized traffic to work and cross through under.

C)Ordinarily, compact gantry cranes are utilized to lift and hold something set up while it's being chipped away at, manufactured, or collected. The heap isn't really being traveled through the office, however the gantry itself can be moved around to chip away at various parts or gear.

D)Versatile gantry frameworks can likewise offer more adaptability than a jib crane or workstation crane. A jib crane ordinarily must be introduced onto a poured solid establishment and whenever it's introduced—it's basically perpetual. A more modest convenient gantry crane can play out a similar sort of work as a jib crane, however can be moved about your office as your business develops and you start enhancing and spreading out stockroom space.

For more information contact us on [email protected] or call us on +971 43336278