Welding Pipe Rotators Or Welding Pipe Rollers

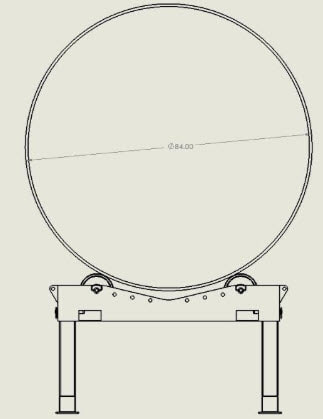

Welding rotators, or pipe rotators, supplement the welding process of pipes, containers, tanks and vessels, as they steady and rotate heavyweight objects with a cylindrical shape. The rotator is equipped with turning rolls which are adjustable to the size of the cylinder keeping it in position while being welded on.

Welding pipe stands are used for rolling and supporting pipe, and handling pipe safely and efficiently. Our pipe stands are typically used as rolling pipe supports in conjunction with welding positioner and column and boom manipulator applications. We offer a wide range of roller pipe stand support roller options for any pipe diameter and weight.

A welding rotator positions the cylindrical jobs whether on light or heavy fabrication shops, the use of a welding rotator provides increased production with reduced labor because it requires less usage of lifting or crane facilities, which also reduces idle time.

Welding pipe stands are used for rolling and supporting pipe, and handling pipe safely and efficiently. Our pipe stands are typically used as rolling pipe supports in conjunction with welding positioner and column and boom manipulator applications. We offer a wide range of roller pipe stand support roller options for any pipe diameter and weight.

A welding rotator positions the cylindrical jobs whether on light or heavy fabrication shops, the use of a welding rotator provides increased production with reduced labor because it requires less usage of lifting or crane facilities, which also reduces idle time.

Adaptable for both automatic and manual welding works, using this type of welding machine helps attain exceptional quality circumferential joints on shells. It is mainly used for welding of pipes, API pipes, heat exchangers, mounted vessels, boilers, LPG bullets, barrels, pressure vessels and tanks.

Welding Rotators or Turning Rolls as they are sometimes called are useful accessories in welding fabrication workshops, designed to keep in place and to rotate heavy cylindrical parts around a horizontal axis, at a constant and steady turning speed in front of a welding head.

Welding Rotators or Turning Rolls as they are sometimes called are useful accessories in welding fabrication workshops, designed to keep in place and to rotate heavy cylindrical parts around a horizontal axis, at a constant and steady turning speed in front of a welding head.

Features Of Welding Rotators

● Adjustable Roller position: Adjustable Roller position is very helpful in adjusting the rollers between the main body so that rollers of different diameter can be adjusted over the same rollers without even buying another size pipe roller.

● Rigid Frame: A Stress analysis has been performed on the rigid body for the testing of the load capability of the frame on which the weight of the pipes depends on.

● Polyurethane Rollers: Polyurethane rollers are being used in this product because polyurethane rollers are weight resistant and can protect the surface of the pipes from being scratched up while rolling.

● Pin Mechanism: Pin mechanism is used to pin the polyurethane rollers on the main frame.

● Adjustable Stand: Adjustable stand is used to adjust the height of the Rigid Frame according to the need and requirement of welding the pipe and according to the comfort level of the welder so that it can provide maximum stability.

● Stable Base: Stable base is being provided for the better stability of the pipes so that it can hold the weight of both the main body and the pipes which are to be carried over it.

● Rigid Frame: A Stress analysis has been performed on the rigid body for the testing of the load capability of the frame on which the weight of the pipes depends on.

● Polyurethane Rollers: Polyurethane rollers are being used in this product because polyurethane rollers are weight resistant and can protect the surface of the pipes from being scratched up while rolling.

● Pin Mechanism: Pin mechanism is used to pin the polyurethane rollers on the main frame.

● Adjustable Stand: Adjustable stand is used to adjust the height of the Rigid Frame according to the need and requirement of welding the pipe and according to the comfort level of the welder so that it can provide maximum stability.

● Stable Base: Stable base is being provided for the better stability of the pipes so that it can hold the weight of both the main body and the pipes which are to be carried over it.

Advantages Of Welding Rotators

- High-quality circumferential welding connections

- Stable and constant turning speed of unwieldy objects during welding

- Reduced lifting and shifting results in minimal risk of damage

- Extra safety during welding work

- Speeding up production

- Conventional turning rolls for cylinderic shapes with a large diameter

- Self-aligning rollers

- Option for rotation in steps

- Option to lock object in place

- Foot pedals for hands-free welding

- Digital displays for monitoring process

- Transportable equipment

Uses of Welding Rotators

Welding rotators are used predominately in the petrol chemical industry, onshore and off shore oil and gas industries, conventional power and nuclear industries and many other fabrication industries where pipes or vessel required to be rotated for semi or automatic welding processes

The use of rotators helps ensure a safe working environment for welders handling large, heavy pipes or vessels. These tools also provide increased efficiency as welders spend less time using lifting or crane facilities to turn pipes during the welding process. With such capabilities, welding rotators are great investments for your workshop.

The use of rotators helps ensure a safe working environment for welders handling large, heavy pipes or vessels. These tools also provide increased efficiency as welders spend less time using lifting or crane facilities to turn pipes during the welding process. With such capabilities, welding rotators are great investments for your workshop.

What To Consider When Loading On Pipe Rotator

- Does the rotator meet the load capacity?

- Is the rotator suitable for required diameter?

- What power or turning speed is needed?

- Which type of wheels are required? (steel, rubber, polyurethane)

- Which number of rolls are needed for the required length of pipes?