What Are Pit Style Dock Leveler

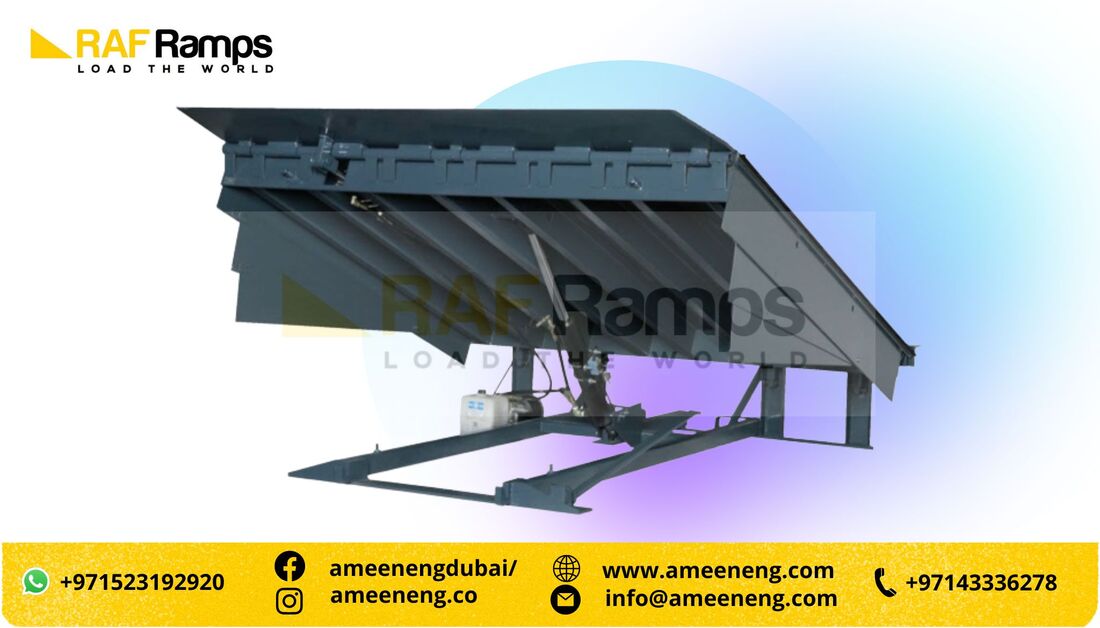

RafRamps has been fabricating and manufacturing dock levelers for more than 8 years to meet the growing demands for effective, safe and economical loading solution for the docks. The simple business philosophy for manufacturing a quality product with user safety in mind continues to be our approach in the marketplace. RafRamp dock levelers continuing success in designing, engineering, and manufacturing loading dock solutions has gained RafRamps dock levelers an excellent reputation within the materials handling industry. There is huge lack of locally manufactured dock levelers in the region which RafRamps have effectively met local demands.

Many clients who have bought Raframps dock levelers have saved thousands of hours on loading and benefited from local support.

Many clients who have bought Raframps dock levelers have saved thousands of hours on loading and benefited from local support.

The dock Leveler bridges the gap to confirm swish and safe transfer of products between vehicle and dock. Manual dock plates and automatic levelers to fit your facility will accommodate differing kinds of vehicles and alternative instrumentality.

Pit style Hydraulic dock levelers square measure designed to change a secure and economical loading and unloading whereas reducing period to a minimum. The result's exceptionally high safety for the transfer of products, preventing any injuries or injury to the instrumentality. Maintenance is straightforward and quick to secure practicality. A bent swing-lip prevents material handling instrumentality from “grounding out”.

Pit style Hydraulic dock levelers feature swing-lip support with checked plates. All impact forces square measure absorbed optimally, avoiding damages and providing long time period. Another outstanding feature is that the lip style with open hinges. This low-maintenance answer guarantees untroubled operation.

The innovative and distinctive RAFRamps tying up system offers good management of the dock radical, dock shelter and door, tired one management unit. some self-explaining buttons create the system simple to control. Separate steering units or advanced wiring are not any longer required.

Hydraulic pit Style dock levelers and lip cylinders increase operational potency and scale back maintenance necessities, leading to a considerably lower value of possession compared to mechanical units. Hydraulic dock radical is a perfect alternative for increased productivity at the dock.

Pit style Hydraulic dock levelers square measure designed to change a secure and economical loading and unloading whereas reducing period to a minimum. The result's exceptionally high safety for the transfer of products, preventing any injuries or injury to the instrumentality. Maintenance is straightforward and quick to secure practicality. A bent swing-lip prevents material handling instrumentality from “grounding out”.

Pit style Hydraulic dock levelers feature swing-lip support with checked plates. All impact forces square measure absorbed optimally, avoiding damages and providing long time period. Another outstanding feature is that the lip style with open hinges. This low-maintenance answer guarantees untroubled operation.

The innovative and distinctive RAFRamps tying up system offers good management of the dock radical, dock shelter and door, tired one management unit. some self-explaining buttons create the system simple to control. Separate steering units or advanced wiring are not any longer required.

Hydraulic pit Style dock levelers and lip cylinders increase operational potency and scale back maintenance necessities, leading to a considerably lower value of possession compared to mechanical units. Hydraulic dock radical is a perfect alternative for increased productivity at the dock.

Our Standard Features of Dock Leveler helps –

- Provide a swish transition for forklifts from warehouse floor to trailer beds – even on out of balance trailers – with a continuing radius rear hinge, two-point crown management, associated an optimized lip chamfer.

- Defend against vacant dock drop-off accidents and facilitate clear finish loading with our exclusive safe lip

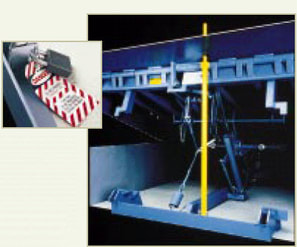

- Protect personnel throughout examination and pit clean out with our exclusive Safe-T-Strut that includes lockout/tagout capability.

- Offer flexibility to be used of three and four wheel forklifts with distinctive structural engineering

Video of demonstration of double cylinder dock leveler before delivery (note it is not inside pit)

WHY choose RAFRamps Dock Leveler ?

We have engineers working who have over the years iteratively improving the design by adopting best engineering technology and processes to be best used regionally. Here are the features of dock levelers :-

A) CE Certified - Due to lack of standard Certified body in Gulf we have adopted CE certification standards and are first and only manufacturer of CE certified dock levelers in Middle East. All our dock levelers are tested according to stringent standards. We are only material handling company in the world where every dock leveler is physically load tested with live load before delivery.

A) CE Certified - Due to lack of standard Certified body in Gulf we have adopted CE certification standards and are first and only manufacturer of CE certified dock levelers in Middle East. All our dock levelers are tested according to stringent standards. We are only material handling company in the world where every dock leveler is physically load tested with live load before delivery.

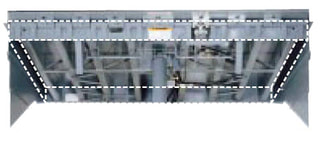

B) GCC Specifications - Most of the manufacturers that provide dock levelers in Gulf Region are based outside the Gulf where there is less harsh conditions compared to the heat and dust in Gulf. We provide dock leveler that has the design and the materials made from durable heat and dust resistant materials. We provide steel tank that does not deform over time due to heat and does not contaminate the stored oil. The inverted cylinder design seen below cleans the dust and maintains long life of the cylinder. The hydraulic pipes provided are heat resistant and long lasting. There is optional hot dip galvanizing option for longlasting antirust properties.

C) Durable Hydraulic System- Hydraulic system is the most important component in the dock leveler. The positioning of both platform and hinge lip ensures high reliability and low maintenance. We have found many conventional hydraulic cylinders are mounted such that when the dock leveler is in closed position the cylinders are exposed to different elements which can reduce longevity of the cylinders in long run. We have made the inverted cylinder which ensures that the dust and dirt settles down and heat and dust are kept away when the dock leveler is closed. Our HYPO motor is durably made to work in conditions up to 65 C which would fit the Middle East climate.

D) Strong Steel construction- The frame is durable and solidly made with beams providing the main support for the structure. We make with strong and durable grade of ASTM A 36 standard steel. A construction system with strong hinges is made to prevent the moving parts of the leveller from maladjustment due to grime.

E) Easy Maintenance - The dock leveler is made for easy maintenance and there is optional support bar to support the platform and lip during service and maintenance these struts are used by maintenance personnel so it does not accidentally close.

Choosing a swish transition dock leveler ends up in fewer worker injuries, less product and instrumentation harm, and low life possession prices. Our styles are invariably evolving to fulfill the challenges you face at the dock.

For more information on dock leveler you can contact us on +971 43336278 or email us at [email protected]

For more information on dock leveler you can contact us on +971 43336278 or email us at [email protected]

We have sold dock levelers to over 125 companies in the region. The following companies are some of our customers.