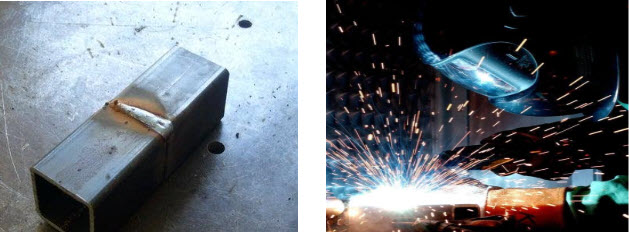

Welding Services

For over 30 years we have been involved in welding and fabrication of steel and aluminum structures for government and private organizations. Our welders are certified according to AWS 1.1 and we have 6G and 3G welders. Please contact us for quote and if possible provide detailed drawings so we can estimate faster and accurately.

There are 4 types of welding which are commonly used in Steel Industries as follows –

- MIG Welding

- TIG Welding

- Stick Welding

- Flux-Cored Arc Welding

- MIG Welding

2. TIG Welding

TIG welding is known because of its quality and applicability. It can be used to weld more metals than any other method of welding, capable of welding metals like steel, bronze, nickel, brass, copper, magnesium, aluminum and gold. Welding in a TIG operation is very precise and clean, allowing for a superior appearance.

TIG welding can be used with such a large variety of metals, the process can be applied to several industries and aid in the creation and repair of many items. This form of welding is commonly used in the aerospace, automotive, repair and art fields industries.

TIG welding is known because of its quality and applicability. It can be used to weld more metals than any other method of welding, capable of welding metals like steel, bronze, nickel, brass, copper, magnesium, aluminum and gold. Welding in a TIG operation is very precise and clean, allowing for a superior appearance.

TIG welding can be used with such a large variety of metals, the process can be applied to several industries and aid in the creation and repair of many items. This form of welding is commonly used in the aerospace, automotive, repair and art fields industries.

3. Flux-Cored Arc Welding -

Flux-cored arc welding is especially useful where the base material to be welded has some amount of scale, rust or other surface contaminants present. It ideally used for welding dense sections that are an inch or more thick because it has a higher weld metal deposition rate.

Flux-cored arc welding is commonly used in piping welding, general repairs, ship building, manufacturing and underwater welding.

4, Stick Welding –

Stick welding is an effective method for welding most alloys or joints and can be used indoors and outdoors or in drafty areas. It's also the most economical welding method and provides the ability to create an effective bond on rusty or dirty metals.

Stick welding is common and versatile it is used in construction, shipbuilding, petroleum, field repair, structural welding, manufacturing, steel fabrication, mining and nuclear industries.

Stick welding is an effective method for welding most alloys or joints and can be used indoors and outdoors or in drafty areas. It's also the most economical welding method and provides the ability to create an effective bond on rusty or dirty metals.

Stick welding is common and versatile it is used in construction, shipbuilding, petroleum, field repair, structural welding, manufacturing, steel fabrication, mining and nuclear industries.