|

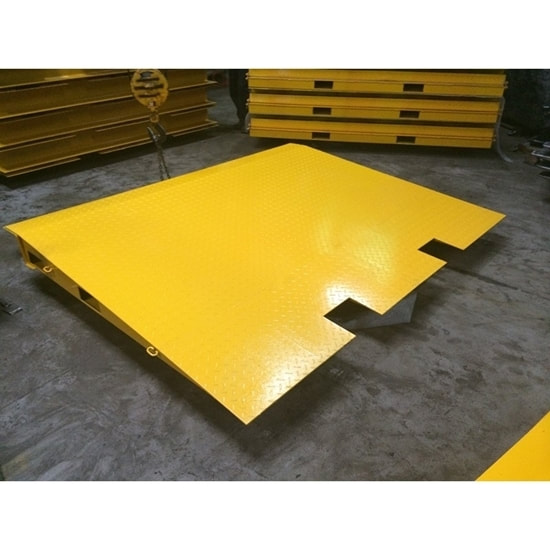

Container ramps provide a safe and efficient way to move containers around. They allow workers to handle heavy loads without having to lift them up by hand. This saves time and energy. Container ramps are used to help people load and unload containers. They are helpful for moving heavy items up and down stairs. They make it easier to move things around your house. A lip plate should be placed in the front end of a ramp. It should form a seamless connection with the container bottom edge. This ensures stability when a forklift moves along the ramp. The lip plate should also prevent the goods from falling down or shaking. This makes sure workers' safety and convenience are guaranteed. There is a lot of confusion when it comes to choosing a container ramp. The two most important things you need to know before you start buying a load container ramp in UAE are:

How to choose the right container loading ramp in UAE? Step 1: The first thing you need to know is that there are different types of containers, and each one has its own specific features. Step 2: You should take into consideration the size of the container when choosing the right ramp. If you have a large container, you should choose a larger ramp. If your container is smaller, you should choose a smaller ramp. Step 3: If your container is too big to fit into your warehouse or shop, you should choose a mobile or a portable loading dock ramp. If your container is small enough to be lifted by hand, you should choose a forklift ramp. Step 4: You should also consider the height of the ramp. If you need a very high loading ramp, you should choose a loading dock ramp. If you need a low loading ramp, you should choose a forklift ramp. Step 5: Finally, you should consider the material of which the ramp is made. If you need a sturdy ramp, you should choose a portable loading dock ramp. If you need a lightweight ramp, you should choose a mobile loading dock ramp. Frequently Asked Questions How to choose the right container loading ramp in UAE? Step 1: The first thing you need to know is that there are different types of containers, and each one has its own specific features. Step 2: You should take into consideration the size of the container when choosing the right ramp. If you have a large container, you should choose a larger ramp. If your container is smaller, you should choose a smaller ramp. Step 3: If your container is too big to fit into your warehouse or shop, you should choose a mobile or a portable loading dock ramp. If your container is small enough to be lifted by hand, you should choose a forklift ramp. Step 4: You should also consider the height of the ramp. If you need a very high loading ramp, you should choose a loading dock ramp. If you need a low loading ramp, you should choose a forklift ramp. Step 5: Finally, you should consider the material of which the ramp is made. If you need a sturdy ramp, you should choose a portable loading dock ramp. If you need a lightweight ramp, you should choose a mobile loading dock ramp. Frequently Asked Questions

2. What is the best container ramp in UAE? There are many types of container ramps in UAE, but the best container ramp is a container ramp that is built to last. Look for a container ramp that has a heavy-duty frame and a strong locking system. 3. What should I look for when choosing a container ramp? When you are choosing a container ramp, you want to make sure that the ramp is strong enough to hold the weight of the container ship. You also want to make sure that the ramp is safe. Look for a ramp that is made out of steel or aluminum. 4. What are the features you get in a container ramp? We offer different capacities of container ramps, one is 7-tons with the protrude mechanism and the other is 10 tons that comes with the grounded mechanism. In conclusion, I recommend that you go for the best container ramp that you can afford. But, don’t just look at the price tag. You should also consider the size of the ramp, its stability, the weight of the ramp, how much it costs to maintain the ramp, and the quality of the materials used to build it. For more information, contact us

0 Comments

Our CE Certified Xtreme Ramps are the highest quality, safest, most durable, and most versatile forklift ramps on the market. We have been producing and selling forklifts and forklift ramps for over 25 years and have earned an excellent reputation for safety, durability, and reliability. We have a long list of satisfied customers, but our testimonials are not the only reason to choose us as your forklift ramp supplier. Al Ameen Engineering has years of experience and expertise in manufacturing and designing of custom made forklift ramps. The company is committed to delivering the best quality products to its clients. The company has an in-house design department with qualified engineers who are capable of creating any kind of ramp you may need. The design department is also capable of modifying the designs as per the client's requirement. Al Ameen Engineering has a well-equipped workshop and a team of skilled technicians who can build any kind of ramp as per your requirement.

In this post, we will tell you about the forklift ramps we offer in UAE, their advantages and features, as well as how to choose the right one for your business. Why Choose our Forklift Ramps? Our front-axle forklift ramps are the most versatile, durable and affordable forklifts in the industry. They are designed with all the safety features and the convenience of the modern forklift. These Forklift Ramps are a perfect solution for companies that need to move large, heavy loads quickly and easily. There are also more benefits of using our Xtreme forklift ramps: Easy To Operate: Hydraulic pumps are usually located outside of the pump engine. This makes them easier to access. Easier access, in turn, reduces the risk of injury because you don't have to get close to any rotating parts, like inside a gearbox. Increased Stability: Our ramps are less likely to tip thanks to its centrally-located cylinder Reduce wear and tear – We build up the ramps with high-quality materials that results in increased and efficient usability. Quick raise: Our ramps are capable of raising two and a half times faster than ramps with a two-cylinder design. Using them can greatly reduce the time it takes to raise the ramp. The Forklift Ramp Safety Features Various Options: We have several options for forklift loading ramps that are made from steel, or aluminum, and come in various sizes. If you buy used, or if you buy new and the forklift is still under warranty, our forklift loading ramps will provide the convenience you need to handle loads more efficiently. Adjustable height: Containers in the MENA region have a range of height from 1.4 m to 1.7 m. Adjustable jacks make it possible for them to be handled by a wide variety of vehicles with different heights (40 ton static load, 25 ton dynamic load). Amazing Traction: Ramps are designed with a grating surface for good traction. They're also serrated, but rectangular in response to increased tire grip. Efficient Accessories: We have been studying lots of different needs and uses in the marketplace, which led to developing a ramp that adapts to the user's needs. One key accessory is the power jack that can be raised or lowered with power Strong Wheels: You can install and remove these ramps easily thanks to the custom Italian made polyurethane wheels with cast iron cores. Different capacities: We have three different standard versions in 7 ton, 10 ton and 15 ton versions. A custom or bespoke version can also be made.

Warranty: All our ramps come with a One Year Warranty. We have customers who've been using them for more than 5 years which is just one way we know they're high-quality. In conclusion, we have a long list of our products. You can check out our website to see more details about the product. We also have a Facebook page, where we post new products and other useful information. Container ramps provide a safe and efficient way to move containers around. They allow workers to handle heavy loads without having to lift them up by hand. This saves time and energy. Container ramps are used to help people load and unload containers. They are helpful for moving heavy items up and down stairs. They make it easier to move things around your house. A lip plate should be placed in the front end of a ramp. It should form a seamless connection with the container bottom edge. This ensures stability when a forklift moves along the ramp. The lip plate should also prevent the goods from falling down or shaking. This makes sure workers' safety and convenience are guaranteed. There is a lot of confusion when it comes to choosing a container ramp. The two most important things you need to know before you start buying a loading ramp are:

How to choose the right container ramp? Step 1: The first thing you need to know is that there are different types of containers, and each one has its own specific features. Step 2: You should take into consideration the size of the container when choosing the right ramp. If you have a large container, you should choose a larger ramp. If your container is smaller, you should choose a smaller ramp. Step 3: If your container is too big to fit into your warehouse or shop, you should choose a mobile or a portable loading dock ramp. If your container is small enough to be lifted by hand, you should choose a forklift ramp. Step 4: You should also consider the height of the ramp. If you need a very high loading ramp, you should choose a loading dock ramp. If you need a low loading ramp, you should choose a forklift ramp. Step 5: Finally, you should consider the material of which the ramp is made. If you need a sturdy ramp, you should choose a portable loading dock ramp. If you need a lightweight ramp, you should choose a mobile loading dock ramp. Frequently Asked Questions Why do I need a container ramp? A container ramp is a small ramp that is attached to a shipping container. It's used for loading and unloading large containers. What is the best container ramp in UAE? There are many types of container ramps in UAE, but the best container ramp is a container ramp that is built to last. Look for a container ramp that has a heavy-duty frame and a strong locking system. What should I look for when choosing a container ramp? When you are choosing a container ramp, you want to make sure that the ramp is strong enough to hold the weight of the container ship. You also want to make sure that the ramp is safe. Look for a ramp that is made out of steel or aluminum. In conclusion, I recommend that you go for the best container ramp that you can afford. But, don’t just look at the price tag. You should also consider the size of the ramp, its stability, the weight of the ramp, how much it costs to maintain the ramp, and the quality of the materials used to build it. For more information, contact us. In the U.S., there are over 2 million forklifts in use, and they’re a common sight at many businesses. These vehicles are responsible for moving heavy loads of goods from one place to another. However, these machines have been involved in numerous accidents, resulting in serious injuries or even fatalities. The forklift ramp is one of the most important parts of the job. A safe and well-designed ramp is the key to keeping workers safe and ensuring that your business runs smoothly. This post discusses how to make sure that your forklift ramps are both safe and easy to use. In this post, we cover some basic forklift safety rules and tips. If you’re a forklift operator or have forklift experience, you should read this article.  What is a Forklift Ramp? A forklift ramp also known as container ramp, is a long, narrow, steel ramp that can be used to load or unload heavy items. A forklift ramp can be used to lift and move heavy objects, such as pallets, large boxes, and even large machinery. Why is Forklift Ramp Safety Important? There are a number of reasons why forklift ramp safety is important. One reason is that forklifts are heavy machines that can cause injuries to the operator if they are not operated correctly. Another reason is that forklifts are dangerous when they are not operated properly. If a forklift is not properly secured, it can cause injury to the operator or damage to the object being moved. How to Install the Forklift Ramp? Installing a portable forklift ramp for a forklift is easy, but it can be dangerous for your employees and for your forklift. A forklift ramp can be dangerous because it can cause your forklift to roll down an incline or off of a slope. It’s important to know how to install a forklift ramp and what kind of ramp to buy. Here are some tips on how to install a forklift ramp safely and effectively: Step 1: Find the right ramp for your forklift: There are different types of forklift ramps, including drop-down, straight-up, and step-up. You should know what type of ramp you need before you buy it. Step 2: The forklift ramp is properly sized: Measure the length of the ramp. The longer the ramp, the more stable it will be. The shorter the ramp, the more likely it will tip over. Step 3: Make sure your ramp is sturdy by first making sure it's level. The easiest way to do this is to check the height of the ramp. If the ramp is not level, adjust it. Also, make sure there are no loose objects, like rocks, that could fall on your operator. If there are any loose objects, remove them. Step 4: Make sure that the surface of the portable forklift loading ramp is smooth. If it's rough, the forklift may slide on it instead of roll over it. To install a forklift ramp safely and effectively, you must be able to perform the following tasks: * Install the ramp correctly * Perform a safety inspection of the ramp before you begin to use it * Inspect the ramp frequently while you are using it * Always keep your eyes on the forklift and the load * Never let your guard down Safety Tips for a Forklift Ramp

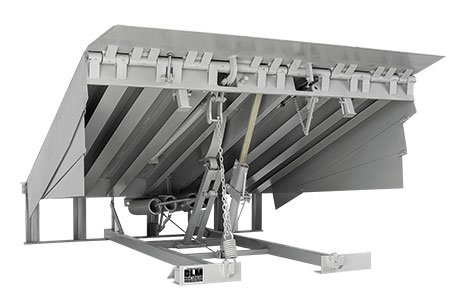

In conclusion, if you’re serious about keeping your workers safe, you need to make sure that you’re using the best forklift ramp design possible. You can customize your own forklift ramp according to your needs, we provide the best designed and sturdy forklift in UAE, contact us for more information. Suppose there are alot of goods in your vehicle that have to be unloaded, but your workers are unable to reach the container with their hands or it is impossible to reach the height of the goods with a forklift. In this case, a loading dock lever comes in help. So, what is a Loading Dock Leveler? A loading dock leveler is a equipment that aids in the leveling of a building's loading dock. This is typically done so that it can be more easily accessed by delivery trucks and other large vehicles. The design of these devices varies greatly, but they all share the common goal of leveling out the surface of the loading dock so that it is easier for larger vehicles to drive on it and access all areas. How To Use A Loading Dock Leveler? A Loading Dock Leveler is a device that helps make loading a truck easier. It is made up of a leveled platform and an electric winch. The winch will pull the product up to the leveler, allowing it to adjust itself to your truck's height. To use a Loading Dock Leveler, first attach it to the back of your truck or trailer. Ensure that your vehicle is close enough so that you can extend the leveler out far enough. Now, position it in front of your dock so that you can easily load products on it from all angles without having to worry about them falling off. Load and unload as you usually would with a loading dock but with more efficiency! Why To Use a Dock Leveler? Loading docks are an important part of every warehouse. They help move goods into the warehouse and out to customers. Levelers come in handy for loading docks because they make it so that the warehouse workers don't have to lift heavy boxes or bags by themselves. A lot of times, people don't understand why they need load levelers and will try to do without them - but in today's world, that leads to a lot of back pain, muscle strain, and lost time. Let us check out the benefits of using a dock leveler.

The dock levelers in UAE are specially designed for the toughest dock operations and have superior durability, reliability and low maintenance costs.If you want to own a long lasting and durable dock leveler for your warehouse, then please contact us. Pit-style Dock Levelers are strong and reliable products that provide a smooth and efficient loading experience. These levelers can be activated manually or mechanically, and come in a variety of sizes. Dock levelers are used to bridge the gap between a vehicle and a loading dock. Manual dock levelers require manual operation by an operator while automatic dock levelers use sensors to adjust automatically. Read the whole article to know more about the types of dock levelers. Types of Dock Levelers Hydraulic dock leveler A hydraulic dock leveler is a device that raises and lowers the height of a load. It can be used to create level platforms for other machines or goods, or to raise them up high enough to load or unload with a forklift. A hydraulic dock leveler is an important piece of equipment in a container yard. These devices help the yard maintain a smooth surface that is even, stable, and easy for forklifts to navigate. A dock can be leveled by installing one or more hydraulic dock levelers with adjustable feet that allow movement of the device up and down to adjust surface height. It usually has 2 basic components: an arm and pressure mechanism which are attached to the machine that requires leveling. Hydraulic Dock levelers are versatile and come with low maintenance cost. The main parts of a hydraulic dock leveler are an elevated platform, adjustable feet, metal plates, hoses, valves, motors with reducers or variable speed drives (VSDs), leveling cylinders with telescopic rams attached at the bottom of each foot plate which operate vertically as well. Mechanical dock leveler The mechanical dock leveler uses a mechanical spring system to raise the leveler and is typically “upward biased.” This means that the springs are angled up and therefore the load is lifted. The mechanical dock leveler has a number of advantages over hydraulic systems in that it does not require any hydraulic fluid, does not use any electricity, and does not heat up. Mechanical dock levelers can be a lifesaver for those without electric motor access to the dock. They also tend to be more reliable than hydraulic models in case of stormy weather or mechanical breakdowns. Air powered dock levelers Air powered dock levelers are used for loading and unloading containers directly on the ground. They are usually fixed at one height, with the container resting on a ramp. Dock levelers are commonly found in commercial ports, wholesalers, and serviced warehouses. This type of dock leveler uses a pneumatic bag system to raise and lower the deck with ease. Obviously this type of leveler requires some power or compressed air to work. Air-powered levelers can be installed faster, with little or no disruption to operations. They also boast reduced service costs and lower maintenance in comparison to mechanical lifts because they are not dependent on engine power or hydraulic fluid to raise and lower them. Choosing the Correct Dock Leveler As a company owner, you know how important it is to have dock levelers in place or your products will not be able to dock. However, it can be difficult to decide which docks are the best for your needs and there are many different types. Here is some information on the different choices and what they offer. The type of docks that you need for your business depends on several factors, such as the size of your load and where you will be transporting products. Most people use hydraulic dock levelers as it can handle heavy loads and is quite inexpensive to maintain. But there are other options as well. So you need to choose the best dock leveler in dubai for loading your goods in a safe way. For more information, contact us. |

Archives

March 2024

Categories

All

|

|

We are a 30 year boutique fabrication company located in Dubai with passion in making great industrial equipment. Our mission is to create high quality products which would save time, money and increase productivity.

|

Quick Links |

Services |

Products |

SUBsCRIBE HERESubscribe to our mailing list to get the updates to your email inbox!

|

RSS Feed

RSS Feed