|

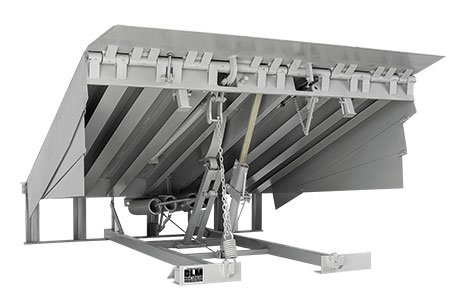

Pit-style Dock Levelers are strong and reliable products that provide a smooth and efficient loading experience. These levelers can be activated manually or mechanically, and come in a variety of sizes. Dock levelers are used to bridge the gap between a vehicle and a loading dock. Manual dock levelers require manual operation by an operator while automatic dock levelers use sensors to adjust automatically. Read the whole article to know more about the types of dock levelers. Types of Dock Levelers Hydraulic dock leveler A hydraulic dock leveler is a device that raises and lowers the height of a load. It can be used to create level platforms for other machines or goods, or to raise them up high enough to load or unload with a forklift. A hydraulic dock leveler is an important piece of equipment in a container yard. These devices help the yard maintain a smooth surface that is even, stable, and easy for forklifts to navigate. A dock can be leveled by installing one or more hydraulic dock levelers with adjustable feet that allow movement of the device up and down to adjust surface height. It usually has 2 basic components: an arm and pressure mechanism which are attached to the machine that requires leveling. Hydraulic Dock levelers are versatile and come with low maintenance cost. The main parts of a hydraulic dock leveler are an elevated platform, adjustable feet, metal plates, hoses, valves, motors with reducers or variable speed drives (VSDs), leveling cylinders with telescopic rams attached at the bottom of each foot plate which operate vertically as well. Mechanical dock leveler The mechanical dock leveler uses a mechanical spring system to raise the leveler and is typically “upward biased.” This means that the springs are angled up and therefore the load is lifted. The mechanical dock leveler has a number of advantages over hydraulic systems in that it does not require any hydraulic fluid, does not use any electricity, and does not heat up. Mechanical dock levelers can be a lifesaver for those without electric motor access to the dock. They also tend to be more reliable than hydraulic models in case of stormy weather or mechanical breakdowns. Air powered dock levelers Air powered dock levelers are used for loading and unloading containers directly on the ground. They are usually fixed at one height, with the container resting on a ramp. Dock levelers are commonly found in commercial ports, wholesalers, and serviced warehouses. This type of dock leveler uses a pneumatic bag system to raise and lower the deck with ease. Obviously this type of leveler requires some power or compressed air to work. Air-powered levelers can be installed faster, with little or no disruption to operations. They also boast reduced service costs and lower maintenance in comparison to mechanical lifts because they are not dependent on engine power or hydraulic fluid to raise and lower them. Choosing the Correct Dock Leveler As a company owner, you know how important it is to have dock levelers in place or your products will not be able to dock. However, it can be difficult to decide which docks are the best for your needs and there are many different types. Here is some information on the different choices and what they offer. The type of docks that you need for your business depends on several factors, such as the size of your load and where you will be transporting products. Most people use hydraulic dock levelers as it can handle heavy loads and is quite inexpensive to maintain. But there are other options as well. So you need to choose the best dock leveler in dubai for loading your goods in a safe way. For more information, contact us.

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

Archives

March 2024

Categories

All

|

|

We are a 30 year boutique fabrication company located in Dubai with passion in making great industrial equipment. Our mission is to create high quality products which would save time, money and increase productivity.

|

Quick Links |

Services |

Products |

SUBsCRIBE HERESubscribe to our mailing list to get the updates to your email inbox!

|

RSS Feed

RSS Feed