|

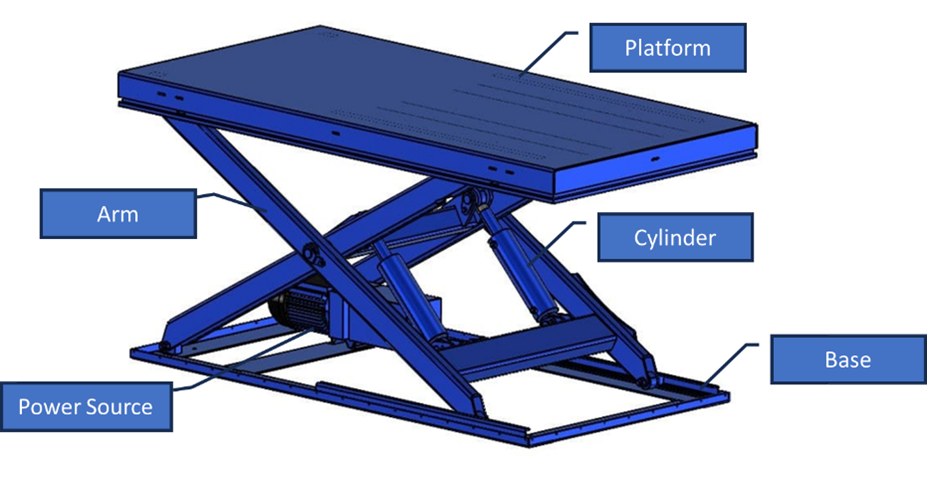

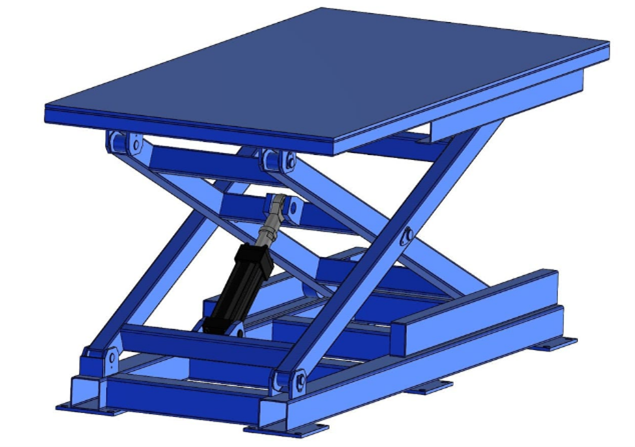

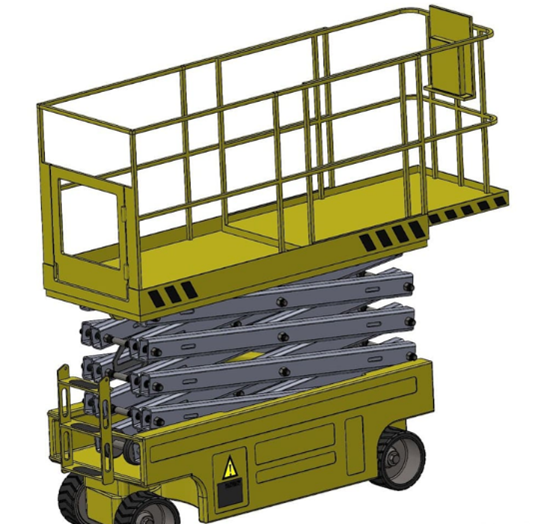

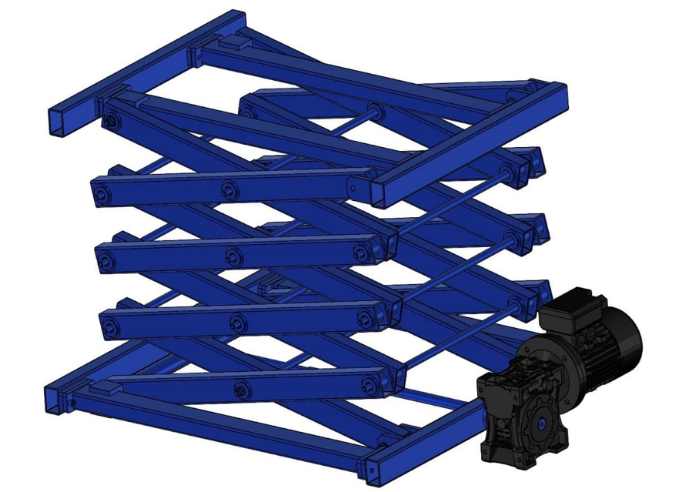

Scissor lift, also called a Lift Table is a type of mechanical lifting platform that is used across various industries to provide access to employees and equipment to elevated and inaccessible areas. It is used to provide safe and efficient access for people and equipment to elevated and inaccessible areas. The scissor or table lift has made a substantial difference to the way industry workers carry out their jobs, saving an incredible amount of time and money while increasing safety at work. SCISSOR LIFT COMPONENTS The key components or parts of a scissor lift include: a. Scissor Lift Platform A scissor lift's platform can be a variety of sizes, forms, and materials. The platform, also known as a lift table, is the working area that supports the load of workers or work objects being raised or lowered by the scissor lift. For fall protection, most units that transport personnel have a platform with guardrails around the perimeter. Lifting and lowering goods and inanimate things are common uses for platforms without rails. b. Scissor Arms The scissor arms are usually a crisscross array of manufactured metal struts that connect the platform to the base. The length of each scissor arm or the number of scissor arms will determine the scissor lift’s maximum working height. The scissor arms raise and lower the platform as they constrict (pull closer together) and extend, and they can be powered by a variety of sources depending on the application. c. Scissor Lift Cylinders One to four compression or expansion cylinders are commonly attached to a scissor lift mechanism. Depending on the specification and operation conditions, these cylinders can be filled with hydraulic fluid (hydraulic scissor lift) or compressed air (pneumatic pump system). The scissor arms and platform are raised or lowered by increasing or decreasing pressure through these cylinders attached to the scissor arms. d. Scissor Lift Base A robust footing made up of strong, stiff brackets is the foundation of the scissor lift mechanism. Tracks guide the rollers at the bottom of the scissor arms in the base. In conjunction with substantial support from the base, these rollers guarantee that the unit is raised and lowered steadily and solidly. The model and application will determine the size and layout of the scissor lift base. e. Scissor Lift Power Source A variety of different power sources can power a scissor lift. These can include everything from self-contained motors that work on various fuels to remote power packs. The working environment of the scissor lift will determine which power source is most appropriate. TYPES OF SCISSOR LIFTS Scissor lifts are classified into four types based on their structure: scissor cylinder type, aluminum alloy (column) type, crank type, and chain type. It is easy to maneuver, use, and hoist, and it has a wide range of home related work, as well as a solid balance function. The different types of scissor lifts include:

The hydraulic fluid or compressed air is moved from the reservoir to the operating cylinders via the scissor lift control system. For upward movement, the hydraulic cylinder pushes outwards, causing the scissor arms to push apart, lifting the platform. The operator releases the hydraulic fluid or reduces the pneumatic pressure level in the cylinder by returning it to the reservoir to lower the scissor lift mechanism, causing the scissor arms to retract. Fixed installation lifts are frequently used to transport items from cars into a building's goods receiving rooms between floor levels. Mobile hydraulic scissor lifts are tiny, lightweight equipment that can be used to move cargo or large objects around a factory or workshop. 2. Diesel Powered Scissor Lift Traditional diesel engines are used to power diesel scissor lifts. They are not as eco-friendly as their electric equivalents because they are noisy and release polluting exhaust fumes when in use. The diesel scissor lifts often have larger platforms and are best used on outdoor construction projects, in well-ventilated inside spaces, and in areas where engine noise will not distract or disturb vital employee communication. Diesel is more cost-effective than gasoline, and it can provide a lot of torque at a low rpm. Heavy-duty units are common, allowing for larger platforms and greater loads. For use on closed job sites, some variations include a hybrid powertrain. Diesel scissor lifts are among the most powerful scissor lifts available, ideal for the most demanding jobs. They are typically hired for work in outdoor sites, and several, such as tough terrain versions, can handle rough uneven ground. Some diesel scissor lifts can offer large deck surfaces and high platform capacities, allowing operators to operate with bulky and heavy equipment. 3. Electric Scissor Lift Electric scissor lifts are more eco-friendly because they are powered by batteries rather than a combustion engine. Due to the lack of exhaust emissions and loud noises when working, they are perfect for interior use. Electric scissor lifts are often smaller, less bulky, and have narrower platforms than diesel scissor lifts. Because they work indoors, non-marking tires are frequently used to prevent floor damage during operations. They're usually used on smaller platforms and have fewer load-bearing capacities than fossil-fuel-powered machines like diesel, gas, or propane. Between job locations, smaller scissor lifts can be transported or towed. Scissor lifts can be mounted on an automated guided vehicle (AGV), a flatbed, or a railcar for specific applications. Rigidity and durability are provided by an all-steel construction and a twin shear scissor stack for long operating life. The electric scissor lift operates reliably and consistently, thanks to high-quality components. These lifts' deep cycle batteries last as long as the job. 4. Rough Terrain Scissor Lift

Rough terrain scissor lifts have more power for working in harsh outdoor conditions. To offer the necessary power for operating across rugged terrain and lifting bigger cargoes, they are often powered by combustion diesel, petrol, or LPG engines. Rough terrain forklifts have increased traction and travel speed, making it easier to maneuver around huge construction sites safely. The major function of these machines is to elevate people and objects off of the uneven ground. They are best suited for difficult environments where they can increase productivity through positive traction, gradeability, and speed. 5. Pneumatic Scissor Lift Pneumatic scissor lifts are driven by air rather than electricity or hydraulics, resulting in a very clean and low-maintenance lift. They are great for operations that aim to be ecologically friendly and reduce their carbon footprint because they use air pressure to raise and lower the lift. The airbag or numerous airbags used in the scissor lift operating system are commonly configured as single, double, or multiple, depending on the size of the scissor lift and its use. The unit is elevated and positioned by an air compressor for working or simple loading and unloading. APPLICATIONS AND BENEFITS OF SCISSOR LIFTS This chapter will discuss the applications and benefits of scissor lifts. The considerations when selecting scissor lifts will also be discussed including inspection, maintenance and common challenges experienced by scissor lifts.

2. Advantages of Scissor Lifts The advantages of scissor lifts include:

CONSIDERATIONS WHEN CHOOSING A SCISSOR LIFT The considerations when selecting scissor lifts include:

0 Comments

Loading or unloading containers from or into the truck can be time-consuming and a tough job. But it becomes less difficult when you use forklift ramps. The purpose of Forklift ramps is loading and unloading goods from a truck or semi-trailer onto trucks, trailers, and railcars. They can be a lifesaver for these 7 reasons:

1, Safe and Convenient The forklift ramp provides an efficient solution for transferring containers between different heights. It allows workers to easily move cargo into and out of the container without having to climb up and down ladders or stairs. This type of equipment will help save time and energy while increasing productivity. In addition, it comes with safety rails that prevent any type of accident. 2, Seconds to Set-Up With its simple design, the installation process is very convenient. The user just needs to place the ramp in the right position and then lock them together. After that, they needn't worry about any other operation because everything else is done automatically. 3, Durability: The featured durable steel construction, heavy-duty ASTM grade steel beams with deep welded structure provide double support for your forklift or hand truck. Also, the strong landing jacks keep the balance between the vehicle and the ramp. So if there is any imbalance, the ramp will not move forward but stay still. In addition, the ramp itself is stable enough to bear heavy loads without shaking. 4, Effortless Mobility One of the most efficient features of a forklift ramp is that it can be moved quite easily. In order to allow you to easily maneuver your equipment to the desired location, most forklift ramps are equipped with wheels. Therefore, you can move the ramp to its destination without much effort. This reduces the time needed for your team to load and unload goods from the truck. 5, Adjustable Height The forklift ramps are quite beneficial as they can be adjusted to different height ranges, according to your need. This feature gives the flexibility to use it for various loading or unloading purposes. 6, Easy Storage: When not in use, it can be folded up easily into a compact size, which takes less space. The forklift ramp is collapsible for easier storage. Half the floor space of the storage can be saved by folding the ramp into a smaller part. 7, Customization: There are different types of Forklift Ramps and they come with different features and usability. Therefore, you have the opportunity to customize your own forklift ramps as per your necessity. There are many benefits of customized forklift ramps: If there are accessories that you want in the forklift ramp, this can be added according to your needs. Moreover, you can get to customize the forklift ramp as per your budget, and also the frequency of the work. For lighter tasks, there are standard ramps which are quite affordable and light-weighted. And if you have to load/unload heavy goods or containers, then you can go for Xtreme ramps. For more information, click here Problem A newly constructed grade-level building without loading docks was leased by this company. They required two loading dock positions for the facility as a practical alternative. The customer and architect were aware of the cost, time, and difficulty involved in building a typical dock approach. Solution Following a discussion with the customer regarding the site conditions, our sales manager recommended the construction of a freestanding dock platform measuring 20mx10m instead of a standing dock. Freestanding loading ramps are perfect for a range of warehouse uses, such as loading and unloading trucks in crowded warehouse areas. All of our self-standing loading dock ramps are built with safety chains, safety railing, and steel bar grating to the highest safety standards. The design and construction of portable loading ramps allow them to be used in almost any outdoor setting and in any kind of weather. They are the ideal solution for outdoor shipping yards that load and unload massive numbers of truck trailers and shipping containers. Moving a portable loading ramp from one warehouse to another is simple. Result

A turnkey solution was provided by Al Ameen to the customer without the need for a contractor or expensive excavation work for the loading dock. As a result of the project, the total cost was significantly less than the original estimate to construct the exterior dock approach. This loading dock was completed on schedule, allowing the customer to commence operations on their schedule without any delays due to excavation and construction. The metal handling and storage containers you use today have the potential to offer your warehouse or business many benefits, especially having an expert to handle all your storage challenges. and logistics operations. However, these are not the only benefits that you will realize when deciding to use a power cord case. Aside from tracking inventory records of products moving in and out of your supply chain, what else can you get out of those metal containers? Learn more about the key benefits of these super convenient wire mesh containers and how they can help take your business to the next level!

A) More Option, More Flexibility Wire mesh containers from leading suppliers like Al Ameen Engineering offer a wide selection. Some previous customers tend to order different sizes and styles on request. In addition, our experts will determine what works best for your business to run more smoothly and be flexible in all operations. Other options also include P.P sheet. print brand logo and sticker on nameplate. B) Less Chance of Theft No matter what type of product or material you are transporting or storing, mesh containers are a very safe choice. Moreover, the roll box like the roll box is also one of Al Ameen Engineering's metal products, which is a very safe type of box, very suitable for supermarkets. In addition, metal, plastic, wood, paint, plastic, rubber and other industrial materials can also be stored using wire mesh containers. C) Space Efficiency A collapsible metal carrying case is another option for you. If you want to make the most of your warehouse space, you can fold these containers when not in use. So it will save more space for other essentials. It will also benefit your warehouse operations and workers as they will have a spare room to use to complete their other tasks or use to store more products and merchandise. D) Keep Inventory Visible Wire box. Increase transparency of inventory throughout the supply chain. This is essential because the contents inside can be seen from the outside and if anything is damaged, it can be repaired immediately instead of leaving a defective product. In addition, during the inventory process, the product does not need to be rejected as it can be easily inspected. In turn, this will also help your employees as they don't have to spend too much time searching for items on the shelves. Al Ameen Engineering offers a wide range of sizes and styles, such as collapsible wire mesh carrying case, collapsible wire carrying case, metal carrying case, steel wire carrying case and more. For more information you can visit our website www.ameeneng.com , Email us on [email protected] or call us on +971 43336278 or +971 523192920. Pipe rollers are an important component of HDD systems, as they are used to support and guide the pipeline as it is being installed. These rollers come in a range of sizes and materials, and are typically chosen based on the specific requirements of the project.

The market for HDD pipe rollers is significant, as the HDD industry has grown significantly in recent years. According to a report by Markets and Markets, the HDD market is expected to reach $7.82 billion by 2023, at a compound annual growth rate of 9.3% from 2018 to 2023. This growth is driven by the increasing demand for underground utilities and the desire to minimize the environmental impact of construction projects. One of the key developments in the HDD pipe roller market is the increasing use of advanced materials. Many companies are now using high-strength, lightweight materials such as carbon fiber and composite materials, which offer improved durability and performance. Another trend in the HDD industry is the use of smart technology and automation. Many companies are now using advanced sensors and control systems to improve the accuracy and efficiency of their HDD operations. This includes the use of real-time monitoring systems to track the progress of the pipeline and detect any potential issues. Overall, the HDD pipe roller market is a dynamic and growing industry, with a wide range of products and services available to meet the needs of customers. As new technologies and materials continue to emerge, it is likely that the industry will continue to evolve and innovate, meeting the changing needs of the market. Horizontal Directional Drilling (HDD) is a method of installing underground utilities and pipelines without the need for open excavation. While it has many benefits, there are also some potential dangers involved in using this technique. One of the main dangers of HDD is the risk of equipment failure. HDD involves the use of specialized drilling equipment, and if this equipment fails or malfunctions, it could result in serious injuries to workers or damage to the surrounding area. Another potential danger is the risk of underground utility strikes. HDD involves drilling beneath the ground, and there is a risk of encountering and damaging underground utilities, such as gas lines or electrical cables. This could cause serious accidents or disruptions to essential services. There is also a risk of environmental damage associated with HDD. If not properly managed, the drilling process can disrupt the soil and vegetation, and there is a risk of contaminating groundwater with chemicals or drilling fluids. To minimize these dangers, it is important to follow proper safety protocols and to use experienced, trained personnel when conducting HDD operations. It is also important to carefully plan and execute the drilling process, and to use appropriate protective measures to minimize the risk of accidents or incidents. Dock levelers are durable and dramatically increase building efficiency. It is essential to provide the dock levelers with precise requirements, such as

A) LENGHT The length of the dock radical is a crucial determinant of the dock radical slope. This slope should be but the utmost grade capability of the loading instrumentality. The length of the docking lever relies on the utmost height distinction between the loading platform and therefore the truck beds. dock levelers area units on the market in lengths from five to twelve linear units. the foremost standard length is eight linear units, which is appropriate for many applications. the traditional most-grade operation for a manual pallet truck is seven-membered. For an electrical pallet truck, the traditional grade is 100 percent. For an indoor combustion self-propelled vehicle, the traditional most grade is V-day. Consult the instrumentality manufacturer for max grade recommendations. Note - These traditional recommendations could vary betting on instrumentation specifications or style changes. The lengths shown in the dock instrumentation table below square measure the minimum dock leveler lengths needed to stay the dock leveler ramp slope among the potential of the loading instrumentation. For height variations or loading instrumentation, the minimum dock leveler length is the height distinction divided by the equipment’s most-grade capability. To move freely and safely over a dock leveler, forklifts and pallet trucks need to have a reasonable amount of ground clearance. Considering pallet jack ground clearances on EOD dock levelers is very important. Pallet jack clearance is a smaller amount of priority on recessed levelers. If their square measure considerations regarding clearances refer to the loading instrumentation provider. B) LIP PROJECTION The dock radical lip should extend a minimum of four in. a regular lip is sixteen in., which comes twelve in. ahead of the dock bumpers. Longer lips could also be required to accommodate the special rear step and rear door configurations on some trailers. The step of a cold trailer could need a lip projection that's fourteen in. or longer past the bumpers. C) LOAD CAPACITY The load capability of the dock radical depends on the gross vehicle weight (GVW) of the self-propelled vehicle. For light-weight to traditional usage, the minimum needed dock radical load capability equals the self-propelled vehicle GVW x 2.5If the precise capability isn't out there, use the following higher capability. employing a higher-than-required load capability can extend the lifetime of the dock leveler. the subsequent conditions have an effect on load capacity: • Forklifts don't drive straight onto the dock leveler • Forklifts with 3 wheels are used • Self-propelled vehicle speeds exceed four mph • Forklifts are equipped with side attachments or fork facet shifters. D) ENVIRONMENTAL CAPABILITY Include perimeter weather seals on site docks to help prevent outside air from entering the building. At cold facilities, make sure the ramp face is insulated. And be careful with condensation on your docks. Problems. distended foam insulation helps forestall the hotter outside air from compression on the face of the ramp. Insulation conjointly saves energy by minimizing the loss of cold air. E) GALVANIZING The zinc metalized spray method is the best technique for eliminating rust. It is galvanized before assemblage to assure complete protection against corrosion. This process usually applies to facilities that handle corrosive materials or are close to harsh environments. Many warehouse trolleys have aided in enhancing storage solutions and the development of better warehouse storage approaches. in addition, those trolleys have benefited from the brief and clean transfer of objects from one warehouse place to another.

It reduces people’s workload and allows them to work extra efficiently and correctly. Owners who recognize cage trolleys’ fees and utility behavior thorough studies before shopping for them. However, even after buying a suitable trolley, the needed performance is not always acquired. It no longer suggests that the trolley is malfunctioning. Maximum of the time, this is due to insufficient and inefficient warehouse cage trolley use. Nowadays, we’ll study some of the maximum commonplace errors people make when the usage of those Roll Cage in UAE and how to avoid them. Taking care of the state of affairs will let you preserve the cage trolley in your warehouse in accurate running order. For instance, check the subsequent. A) No to man Trolleys but Cage Trolleys: The usage of a warehouse roll cage and trolley as a man trolley is one of the most not unusual blunders people make in a warehouse. Even though to deal with and produce huge weights. The advent of these cages does now not imply hoisting men upon utilization. It's far something that warehouse employees regularly do, but, it isn't always recommended at the same time as the use of these antique cages and bins. As a result, never make this error with your warehouse’s containers and cages. B) Prioritize Double-Checking Every other normal blunder made while the usage of cages and trolleys is failing to inspect the cage earlier the use of it. Even though the garage was ok the remaining time you used it, it’s a terrific concept to double-test it whenever you use it. It will make certain that things are loaded safely into the Roll Cage. As a result, inspect the roll container cages thoroughly earlier than using it. C) Preserving storage Cleanliness Keeping it smooth improves the first-class and efficiency of the cage or cart. It protects the garage and prevents rusting and corrosion. Al Ameen Engineering makes warehouse cage trolleys distinctly easy to hold. It additionally provides brilliant visibility for the items and items saved inside. It also offers the goods and matters held internal awesome visibility. It is an extraordinary exercise that top storage cage providers and producers suggest. As a result, constantly make sure you’re no longer making these errors and that you’re following the safety policies in your warehouse. If you have any additional questions or doubt, please do not hesitate to call us for Roll Cages. Our crew of specialists might be satisfied to assist you. Roll container cages is a need that every business could depend on for many years. These cages could make each complex assignment very clean and conceivable on both ends. A part from that, a warehouse wanting for an efficient operation will no longer be a dream as a roll cage field could make it happen!

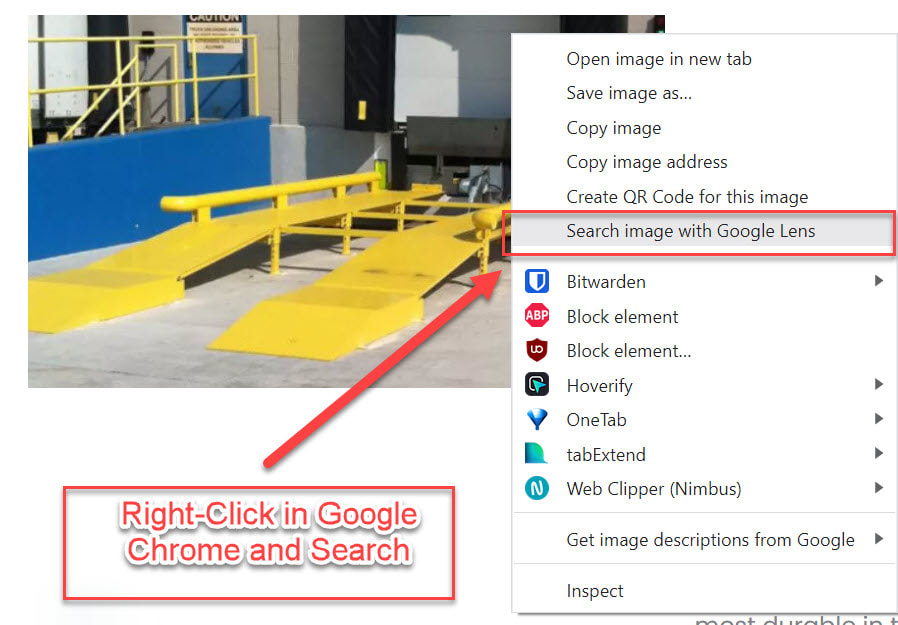

Safe execution comes with many perks and advantages and is constantly required for a team of employees and customers. Why? this is due to the fact that some mismanagement could not only negatively impact the operation of the logistics and material handling system, but could also result in workplace accidents that could severely harm the firm. What guidelines must each warehouse adhere, in order to prevent these occurrences? Following these straightforward execution safety recommendations from Al Ameen Engineering can help you grow your business and implement the best logistical support service. A) Ineffective pulling and pushing up Have you noticed that the majority of warehouse accident reports include the roll container cages being accidentally pushed or pulled up? This frequently happens as a result of bins having an excessive amount of loading capacity. Therefore, the body of employees lifts it up by pushing or pulling it without realizing that the container is overweight. Additionally, some people handled it hastily. Being cautious is essential when working with a roll cage warehouse, especially when using the cages on downhill slopes. Rushing can desire to result in a serious accident. Al Ameen Engineering typically advises performing one additional round with less weight to be secure. B) Travel on Inclines and Uneven Ground Transferring the roll container cages over the uneven ground may be fraught with chance. Warehouse employees or employees are suggested to take intense care in such situations. Consequently, to prevent any risk from taking place, why no longer flow a few heavy items piece by way of piece? Or gradual things down and make certain that the floor for roll box cages to tour. To avoid the field from toppling over or going for walks out of manipulate, numerous personnel to assist pass items is advisable. C) Casters – The Point of Contact The casters of the roll field cages are used for a smooth movement across the ground and need to be well maintained to avoid problems. When a unmarried a part of the box receives damaged, especially its wheels, it may cause the roll cage to paste at the same time as affecting the movement of the unit. And due to the fact things are unpredictable from happening, any small hassle can affect the whole operation. Thus, it may cause safety troubles between the roll field and different surfaces. Any enterprise using a roll box cages should do everyday preservation wherein the wheels of each cage are checked for any defects D) Lack of Supervision & Knowledge Loss of knowledge and supervision of employees is likewise another not unusual reason for accidents with roll container cages. These cages won’t be coping with lightweights. For this reason, proper knowledge and supervision is a must. You should verify the authenticity of the Ramp Manufacturer before you buy a ramp as penalties of buying a wrong ramp can be severe. This is because the ramp manufacturer can make a difference in the quality of your ramp. The verification process is not difficult. You need to find out some essential information about the company before you decide to make a purchase with that company. Here are things you need to verify before buying a ramp. 1, Check Trade license For AuthenticityThe trade license is one of the most important documents when it comes to verifying the authenticity of a ramp manufacturer. The ramp manufacturer needs to be a licensed and certified company. Make sure they are in the business for more than a decade of experience before purchasing the ramp. There are many that claim they have been business for more than 10 or 20 years, check the issue date of the license and verify if the manufacturer is saying the truth. In Al Ameen Engineering LLC, one can view the trade license or any certificates, you will find Dubai branch have been in existence for more than 24 years, this assures the clients that the company follows the guidelines, rules, and safety measures.

|

Archives

March 2024

Categories

All

|

|

We are a 30 year boutique fabrication company located in Dubai with passion in making great industrial equipment. Our mission is to create high quality products which would save time, money and increase productivity.

|

Quick Links |

Services |

Products |

SUBsCRIBE HERESubscribe to our mailing list to get the updates to your email inbox!

|

RSS Feed

RSS Feed