|

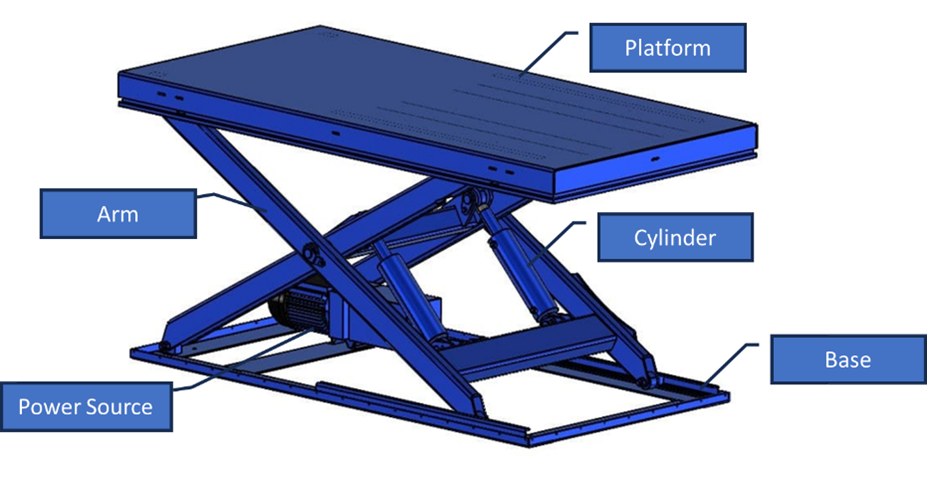

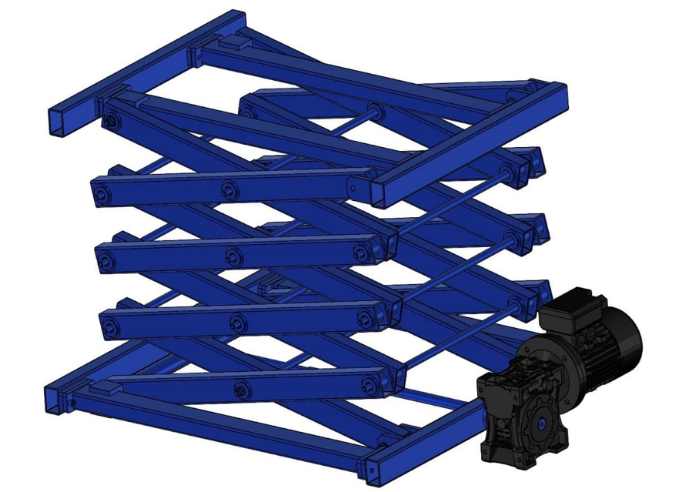

Scissor lift, also called a Lift Table is a type of mechanical lifting platform that is used across various industries to provide access to employees and equipment to elevated and inaccessible areas. It is used to provide safe and efficient access for people and equipment to elevated and inaccessible areas. The scissor or table lift has made a substantial difference to the way industry workers carry out their jobs, saving an incredible amount of time and money while increasing safety at work. SCISSOR LIFT COMPONENTS The key components or parts of a scissor lift include: a. Scissor Lift Platform A scissor lift's platform can be a variety of sizes, forms, and materials. The platform, also known as a lift table, is the working area that supports the load of workers or work objects being raised or lowered by the scissor lift. For fall protection, most units that transport personnel have a platform with guardrails around the perimeter. Lifting and lowering goods and inanimate things are common uses for platforms without rails. b. Scissor Arms The scissor arms are usually a crisscross array of manufactured metal struts that connect the platform to the base. The length of each scissor arm or the number of scissor arms will determine the scissor lift’s maximum working height. The scissor arms raise and lower the platform as they constrict (pull closer together) and extend, and they can be powered by a variety of sources depending on the application. c. Scissor Lift Cylinders One to four compression or expansion cylinders are commonly attached to a scissor lift mechanism. Depending on the specification and operation conditions, these cylinders can be filled with hydraulic fluid (hydraulic scissor lift) or compressed air (pneumatic pump system). The scissor arms and platform are raised or lowered by increasing or decreasing pressure through these cylinders attached to the scissor arms. d. Scissor Lift Base A robust footing made up of strong, stiff brackets is the foundation of the scissor lift mechanism. Tracks guide the rollers at the bottom of the scissor arms in the base. In conjunction with substantial support from the base, these rollers guarantee that the unit is raised and lowered steadily and solidly. The model and application will determine the size and layout of the scissor lift base. e. Scissor Lift Power Source A variety of different power sources can power a scissor lift. These can include everything from self-contained motors that work on various fuels to remote power packs. The working environment of the scissor lift will determine which power source is most appropriate. TYPES OF SCISSOR LIFTS Scissor lifts are classified into four types based on their structure: scissor cylinder type, aluminum alloy (column) type, crank type, and chain type. It is easy to maneuver, use, and hoist, and it has a wide range of home related work, as well as a solid balance function. The different types of scissor lifts include:

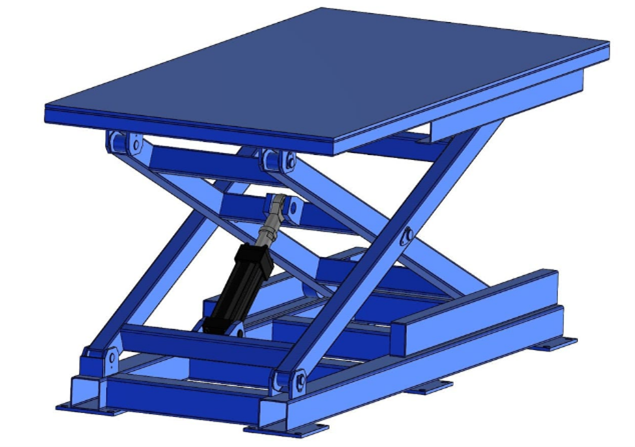

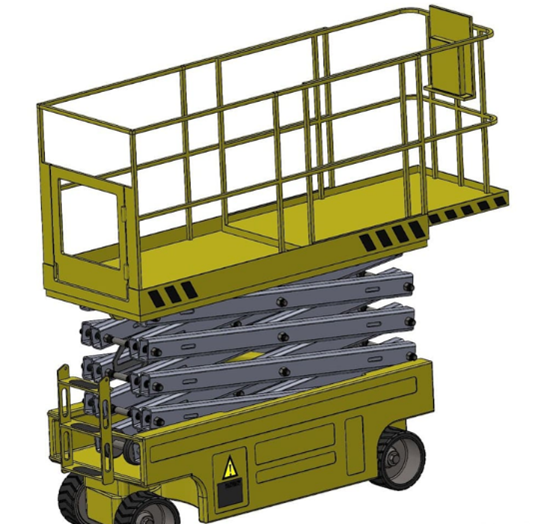

The hydraulic fluid or compressed air is moved from the reservoir to the operating cylinders via the scissor lift control system. For upward movement, the hydraulic cylinder pushes outwards, causing the scissor arms to push apart, lifting the platform. The operator releases the hydraulic fluid or reduces the pneumatic pressure level in the cylinder by returning it to the reservoir to lower the scissor lift mechanism, causing the scissor arms to retract. Fixed installation lifts are frequently used to transport items from cars into a building's goods receiving rooms between floor levels. Mobile hydraulic scissor lifts are tiny, lightweight equipment that can be used to move cargo or large objects around a factory or workshop. 2. Diesel Powered Scissor Lift Traditional diesel engines are used to power diesel scissor lifts. They are not as eco-friendly as their electric equivalents because they are noisy and release polluting exhaust fumes when in use. The diesel scissor lifts often have larger platforms and are best used on outdoor construction projects, in well-ventilated inside spaces, and in areas where engine noise will not distract or disturb vital employee communication. Diesel is more cost-effective than gasoline, and it can provide a lot of torque at a low rpm. Heavy-duty units are common, allowing for larger platforms and greater loads. For use on closed job sites, some variations include a hybrid powertrain. Diesel scissor lifts are among the most powerful scissor lifts available, ideal for the most demanding jobs. They are typically hired for work in outdoor sites, and several, such as tough terrain versions, can handle rough uneven ground. Some diesel scissor lifts can offer large deck surfaces and high platform capacities, allowing operators to operate with bulky and heavy equipment. 3. Electric Scissor Lift Electric scissor lifts are more eco-friendly because they are powered by batteries rather than a combustion engine. Due to the lack of exhaust emissions and loud noises when working, they are perfect for interior use. Electric scissor lifts are often smaller, less bulky, and have narrower platforms than diesel scissor lifts. Because they work indoors, non-marking tires are frequently used to prevent floor damage during operations. They're usually used on smaller platforms and have fewer load-bearing capacities than fossil-fuel-powered machines like diesel, gas, or propane. Between job locations, smaller scissor lifts can be transported or towed. Scissor lifts can be mounted on an automated guided vehicle (AGV), a flatbed, or a railcar for specific applications. Rigidity and durability are provided by an all-steel construction and a twin shear scissor stack for long operating life. The electric scissor lift operates reliably and consistently, thanks to high-quality components. These lifts' deep cycle batteries last as long as the job. 4. Rough Terrain Scissor Lift

Rough terrain scissor lifts have more power for working in harsh outdoor conditions. To offer the necessary power for operating across rugged terrain and lifting bigger cargoes, they are often powered by combustion diesel, petrol, or LPG engines. Rough terrain forklifts have increased traction and travel speed, making it easier to maneuver around huge construction sites safely. The major function of these machines is to elevate people and objects off of the uneven ground. They are best suited for difficult environments where they can increase productivity through positive traction, gradeability, and speed. 5. Pneumatic Scissor Lift Pneumatic scissor lifts are driven by air rather than electricity or hydraulics, resulting in a very clean and low-maintenance lift. They are great for operations that aim to be ecologically friendly and reduce their carbon footprint because they use air pressure to raise and lower the lift. The airbag or numerous airbags used in the scissor lift operating system are commonly configured as single, double, or multiple, depending on the size of the scissor lift and its use. The unit is elevated and positioned by an air compressor for working or simple loading and unloading. APPLICATIONS AND BENEFITS OF SCISSOR LIFTS This chapter will discuss the applications and benefits of scissor lifts. The considerations when selecting scissor lifts will also be discussed including inspection, maintenance and common challenges experienced by scissor lifts.

2. Advantages of Scissor Lifts The advantages of scissor lifts include:

CONSIDERATIONS WHEN CHOOSING A SCISSOR LIFT The considerations when selecting scissor lifts include:

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

Archives

March 2024

Categories

All

|

|

We are a 30 year boutique fabrication company located in Dubai with passion in making great industrial equipment. Our mission is to create high quality products which would save time, money and increase productivity.

|

Quick Links |

Services |

Products |

SUBsCRIBE HERESubscribe to our mailing list to get the updates to your email inbox!

|

RSS Feed

RSS Feed