|

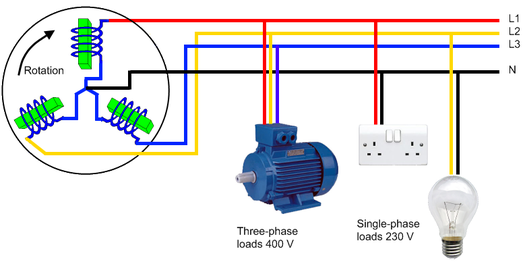

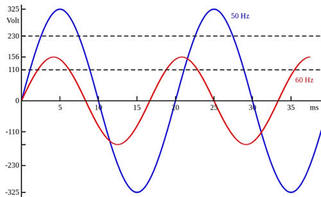

Did you plan to fabricate a new or modify existing forklift ramp? If you are installing hydraulic landing jacks then read this post as it can save you lots of money before you make mistake in buying one. Though this guide is not comprehensive it is good enough for you to understand your needs before welding a hydraulic cylinder jack to your fabricated ramp. So what do you have to know? a, Single Phase or Three Phase Do you have single or three phase electric installation in the place where you will place your yard ramp? If you are ordering electric powered hydraulic systems then you have to read this section. Single phase powers most of the non-commercial and industrial outlets. Triple phase is used mainly in industrial firms which require high powered output on some machines. Ask your engineers or technicians and know this before hand before ordering custom steel fabricated ramps. b, Frequency In UAE the motors with 50Hz are used whereas in neighboring Saudi Arabia 60Hz is used. Ask the frequency of the pump motors of your power pack to know what you are getting. c, Manual Lever or Control Panel Manually lever is same as mechanical which has almost all the components same as the electric powered only difference is control panel unit. Lever unit costs about -$1000 to $1500 less (Dhs 3000-4000) and advantage of lever powered is that it can be used anywhere as it is not electric powered. Electric powered system is powered and you have to know if it is powered by single or triple phase. In the control panel other than up and down there should be optional emergency button. d, Lifting Weight If you are planning to use the ramp to lift 5 tons then you will have to add the weight of the ramp plus the forklift and the carrying material weight to get rough maximum load the ramp can carry. The reason is most of the load falls on the landing jack so it will have to carry maximum load to prevent load stress. If for example you want to carry 5 tons of goods then total weight you will have to plan is 4 ton weight of the ramp plus 5 ton weight of the goods plus 3 ton weight of the forklift ramp plus 3 tons grace weight space. Not that there is difference between static weight or ramps that sit still and the ramps that have moving loads. More weight requires more powerful hydraulic pump and thus it is more expensive. e, Anti-leak Safety feature If there is leak in the valve of hydraulic the cylinder will give in under the weight and will slip which can be hazardous and dangerous. To prevent this there is an optional system put in place which prevents the cylinder to slip in case there is a leak. Ask your ramp manufacturer if they have this option in place for the ramp. f, Hold and Release or Single Press When you decide to get electric hydraulic option when you decide to install hydraulic ask if you want Single Press or hold and release. The difference is that in single press, hydraulics goes up and down with press of a button but in hold and release the hydraulic stops moving up or down when you take stop pressing the switch. Single Press is good if you know the height of the platform where the forklift or any goods will get up whereas hold and release is good for variable heights. Check out our Forklift Ramps Here

1 Comment

19/12/2014 04:09:18 am

Heavy duty ramps are essential to huge industries. I've been working on an auto industry for a long time now and i could really say that ramp is one of the vital tool that we need in production. I cant really imagine lifting those heavy auto parts myself. haha.

Reply

Your comment will be posted after it is approved.

Leave a Reply. |

Archives

March 2024

Categories

All

|

|

We are a 30 year boutique fabrication company located in Dubai with passion in making great industrial equipment. Our mission is to create high quality products which would save time, money and increase productivity.

|

Quick Links |

Services |

Products |

SUBsCRIBE HERESubscribe to our mailing list to get the updates to your email inbox!

|

RSS Feed

RSS Feed