|

Recently we were approached by military consultants to build a customized ramp to carry 25 tons (weight equivalent to 10 Toyota Land cruisers). This was challenging project as their client did not provide complete specifications on their requirements. RAFramps (a division of Al Ameen) consultants analyzed worse case scenarios to build custom ramps by asking questions about the clients needs and came up with design that is durable and require less maintenance over the time. After a week of designing and initial tests, the client approved the designs and fabrication was done in record time to meet the client deadlines. We manufactured and delivered in record time to 2 units of 25 tons loading ramp to the United States Army in Kuwait. Forklift loading ramps from RAFRamps offer versatility, durability, and efficiency to any loading or unloading procedure. At RAFRamps we recognize the necessity for high-performance, low-maintenance equipment in any workplace. For this reason, we provide different variety of forklift loading ramps and loading ramp accessories that are designed to optimize any warehouse operation. That’s is why clients like United States Army, DP World, Dry Docks and many government institutions trust us with manufacturing material handling solutions for the client. If you want to 30 point questions and came up with customized ramp two pieces which client used to load and unload heavy duty vehicles. Please contact us for ramp inquiry and customizing ramp according to your needs.  Finished Ramp Finished Ramp

0 Comments

What is A Loading Ramp? A loading ramp is an inclined surface that allows people or vehicles to load, unload, move around on or store items at different levels. A loading ramp can be used as part of a building's design or it may be added later when needed. Al Ameen has been manufacturing standard and custom designs for more than 10 years where major clients use RAFRamps to load containers in UAE Features to Consider When choosing a container ramp, there are several features to consider:

Why A Load Container Ramp Is the Best Option? 1. Safety and Convenience The first benefit that comes up when using a container ramp is its safety feature. The container ramp helps to keep your workers safe while they are working on top of containers. This kind of tool is designed to provide an easier and safer method of transferring cargo between vehicles and containers. When it comes to lifting heavy loads, there will always be risks involved. However, if you want to avoid accidents during moving operations, then you should consider investing in a container ramp. 2. Efficient Handling Work A container ramp system is designed for quick access to the top of a standard-sized shipping container. The design allows easy movement from one side of the container to another without having to climb over or around it. Mostly container ramps are made with heavy-duty steel construction that will last through years of use. They also come equipped with an adjustable locking mechanism so they can be locked into place when not being used. These container ramps have been tested by professional forklift drivers who found them very useful and safe. 3. Shipping Cost Saved Shipping cost is one of the most important factors that affect your profit margin. If you want to save shipping costs, then container ramps are an ideal choice because they're economical and don’t cost a lot. 4. High-Quality Material

We only choose high-quality materials like steel and aluminum alloy to make sure it lasts long. Besides, we provide a lifetime warranty if there is any problem after installation. 5. Customized Service Container ramps offer quick access for the user. They are easy to use and require no tools or special skills. Our ramps are made of durable steel that will last a lifetime. You can customize your own container ramps according to your work needs. Our light-duty 7 tons container ramp weighs 330kgs, which should suffice for loading/unloading larger but not too heavy items.Moreover, we also offer a heavy-duty 10-tons container ramp, which is best for loading/unloading heavy containers. Our container ramps have been tested by many users over time and it's proven itself as one of the best on the UAE market today! For more information, please click here. When it comes to loading containers onto a truck, there are many safety measures you need to take. You should always be careful while loading the container. Here are a few rules, you should follow while loading a grounded container, to make the operation safe and convenient. 1, Proper Planning: Ensure a well-planned load distribution prior to the loading process. This will ensure that no more than half of the container bears more than 60% of the payload. You should have all the necessary tools ready for the safe loading of the container into the truck. 2, Preparation of the ground: The loading process should start with a careful inspection of the ground surface, which should be level and free of obstructions such as rocks, trees, holes or loose materials that could shift during loading. 3, Use a Forklift: In order to safely load a grounded container, it is best to use a forklift. The ground should first be watered down so that the forklift has a good grip on the earth. Forklifts make it easier to load and unload goods. Make sure the container is level and square before loading it with the help of a forklift. They have a metal prong that holds the container upright while it's being moved. This prong needs to be lowered down slowly so that you don't tip over your cargo. 4, Safe Loading: The load should be shifted as evenly as possible so that it can be safely moved. It is important to make sure that the container is grounded before it is loaded on a flatbed. The last thing you want to happen is for the container to move and cause an accident. 5, Use container ramps: A container ramp is a fastest and most efficient solution to load containers more quickly. It acts as a small bridge between the ground and the container and therefore makes the operation smooth.

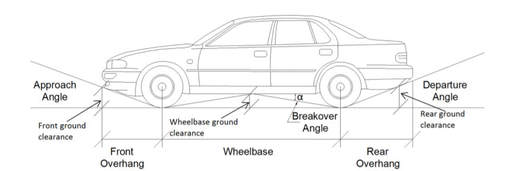

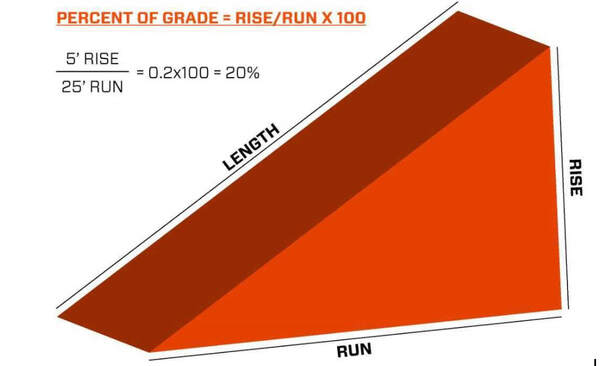

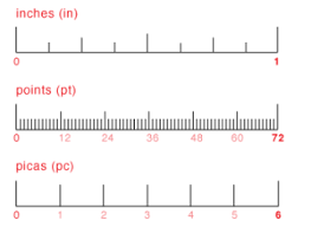

It's safe to say that using a ramp is more beneficial in the long run when it comes to loading heavy objects. It lowers the risk of injury, reduces health risks, and decreases the likelihood of a load spilling or falling. To get the best and heavy-duty ramps to load containers in UAE, please contact us. Operating a forklift on an incline is one of the operations that has to be done very carefully, regardless of the driver's experience. If you are loading/unloading a truck container in uae, ensure you take safety steps or precaution during the loading/unloading process. The important factor that a driver or an operator must know is the gradeability of the forklift. Gradeability is the grade in which a forklift can climb and stop at full capacity. You can calculate the gradeability of your forklift as shown below When you have finally calculated the gradeability of your forklift ( the highest gradeability a forklift can have is 40% ) , make sure your keep the below points in mind when you operate it.

- Always carry a load with the forks pointed upward, to avoid the load falling off the forks. - Do not steer suddenly to change directions. - If the forklift is carrying no load make sure the forks are pointing downwards for better traction. - Keep safe distance from the edge of the ramp (Always choose a ramp with side railing and CE certified ramps which follows all the safety measures) - Always follow the instructions given by the forklift ramp manufacturers, since the ramp is designed with convenience and safety in mind. You don't want to push aside their recommendations. - When getting down from the ramp, it is advised to get down in reverse. - If you find any problems with the ramp, contact the experts for supervision immediately. - Take assistance of a co-worker if the load is blocking the drivers view. - Operate the forklift carefully and not in a hurry. - Always choose a ramp with good wheels which can provide traction to avoid any kind of slipping, which saves both time and fuel. - Always choose a slope the experts recommend, since they recommend a ramp with a specific slope only after careful analysis of your operations and gradeability in mind. - Always choose a ramp which is durable and safe, so that your employee can work with a peace of mind, rather than opt for cheaper alternative, which may or may not breakdown and cause accidents in the long run. - Do not under any circumstance follow the ramp up the slope. - If you are planning to load or unload many trucks then use mobile yard ramp or forklift ramp. We have more than 15 versions of forklift ramps, if you want to seek advice for selecting best ramp for your needs then contact one of the sales representative for more details.  Working at height can be risky if you do not use safe and appropriate equipment to lift yourself. When it comes to working at a specific height, the safest equipment to lift the laborers would be a man safety cage, also known as a forklift man cage. A forklift man cage can be used for various purposes. Using a forklift safety cage will not only save your time but also will help to complete the tasks at higher places without any risk or danger. In this article, we will let you know the purposes of a forklift man cage, how safe it is, and also how to safely work at height by using it. What Are The Purposes Of Using A Forklift Mancage? A safety mancage is most commonly used for repair and construction works. It helps in lifting one or more people at a certain height to perform some specific task. A forklift man cage is a safe scissor lift alternative, which can be used for agriculture, industrial, and also for personal rescue. Using a safety mancage is quite cost-effective, but there are chances it can be dangerous sometimes. A mancage is not acceptable to use in some cases. It cannot be used for production-related tasks or work related to stocktaking. How Safe Is A Forklift Mancage? Mancage dubai provides a secure cage setting in which to perform a variety of maintenance and inspection tasks. Forklift mancages are constructed with durable and heavy-duty steel, which makes them stable and solid. There are no chances of slipping or falling from the mancage, as they are surrounded by high-strength rails on all sides for safety and security. They come with safety door pins, which make the door strong and rigid. Moreover, they feature an automatic self-locking gate that makes it easy for people to enter or exit the mancage without any hassle. For easy storage and transportation, the access platform comes with a hinged back guard. There are also safety restraint tie-downs for attaching the safety belt, kick-plate on all sides, and safety harness hook points. The man basket can be also be used in rainy weather or in the wet as it comes with a self-draining system and an anti-slip floor. All these features ensure that it is quite safe to use a mancage. What Precautions Should Be Taken To Use A Man Cage? You have to take some safety precautions before using a forklift man lift cage to prevent fall or accidents and to use it safely. Let us look at the steps you need to follow:

Essential Safety Tips Forklift Mancage Do’s

Don’ts

These are some of the important safety tips you should follow while using a forklift mancage. Using a personnel-basket is quite easy and needs minimum maintenance. It is the safest work platform when working at height. Dropdeck trailers or flat deck trailers are manufacturing marvels designed to help transport a wide array of cargo and containers. However, when you go looking for a trailer, you need to know what specifications you have, whether you can purchase or rent a commercial trailer or you require a custom flat deck trailer. While nearly every trailer will have similarities in design and construction, the length, weight and purpose will vary. Therefore, when you have a job requiring a trailer transport, consider the following six things. A) Size - What size cargo are you looking to transport? Will you consistently carry containers this size, or will your jobs vary from trip-to-trip? If you only move 20- or 40-foot containers, then you can look for a trailer that size. However, if you carry varying container lengths, then there are manufacturers who make extendable trailers. Knowing the size of your typical cargo will probably be one of the most critical decisions you make in the design and purchase of your flat deck trailer. B) Durability and Resale Value - Next, you will want to think about the durability and resale value of the trailer. While you may have no intention of selling the trailer once you purchase it, businesses rely on the sustainable value of assets, and vehicles are notorious for losing value. However, as tools and machinery are concerned, trailers are capable of maintaining significant value, especially when made from quality materials and properly maintained. Therefore, if your trailer purchase is for a business, consider the time value of your purchase. C) Load Capacity - Before you purchase a trailer, you will need to review local laws and regulations, as well as the load capacity of your trailer. Many flatbed trailers range in capacity from ten to 80 tons. The needed capacity will also alter the design of the trailer. For example, heavier loads will require a chassis with three axles made of high-yield materials. Attempting to carry heavier loads on smaller, less capable trailers may result in damage or injury, and it is likely illegal. D) Axles - Just like there are laws regulating the load capacity of trailers, there are also laws governing the configuration of axles. Therefore, when designing or considering different axle configurations, choose options that are permissible. Also, ensure that whatever you select will support not only the weight of your cargo but the type of wheel assembly you prefer. Purchasing the correct and legal axle configuration will ensure that your trailer remains useful for years to come. E) Tires - When it comes to trailers, the government tries to regulate in their entirety to ensure the safety of others on the roadways as well as the operator. However, those regulations can restrict the number of available options for trailer purchases. For example, some owners feel that a single tire system would suffice for their operations. However, a municipality may not permit such a configuration. Therefore, always check with local trailer regulations before buying anything. F) Use and Function -

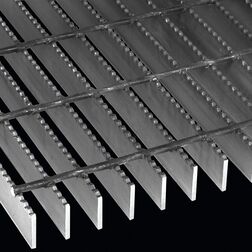

Last, you need to know the function and purpose of your needed trailer. For example, are you in need of a trailer that uses a tilt operation for easy unloading or an extendable trailer for a variety of cargo loads? Perhaps you only have a need for a traditional trailer and nothing fancy. Whatever your needs, knowing will make your purchasing decision easier, allowing you to narrow down your search and pinpoint a target budget. In the end, the type of flat deck trailer you need will depend on your specific requirements and the type of cargo or containers you expect to transport. However, if you would like some help to discover your available options, then contact Al Ameen Engineering. RAFRamps forklift ramps are manufactured in the Middle East Region. The undercarriage of the ramp is maintenance free. The ramp has two screw mechanical jacks which hold static weight of 40 tons and dynamic weight of 80 Ton. RAFRamps forklift ramps are the first CE certified manufacturer of the ramp in the Middle East Region. We are the only company to physically load test every ramp before delivery. Above all, we care you get the correct product to deliver safe and efficient results for your loading and unloading needs. A) Safety Railing on the sides of the ramp – Safety can continuously be a key focus at RAFRamps Forklift Ramp. it's commonplace that area unit ramps provide provide safety railing on each aspect of the ramp. We tend to aim to cut back the danger of accidental run-off and alternative loading mishaps with these high-performing safety curbs B) High Traction Grating on top of the ramp – RAFRamps Forklift Ramps uses a high-traction grating fabricated from high-strength soft-cast steel. Grating bars spacing between bars that flip water, snow, and alternative rubble will simply fall flat. This grating prevents buildup and provides high-quality traction in harsh environmental conditions. C) Larger Width – RAFRamps Forklift ramp manufacture forklift ramp with width of 2.3m whereas the client can use both 3-ton and 5- ton forklift where as other competitor ramp provide only width of 2.1 m where you cannot accommodate a 5-ton forklift because of the less width. D) Custom Design Ramp – The same freight handling installation simply won’t give an equivalent profit in each area. For this reason, we have a tendency to take nice pride in giving premier custom steel fabrication and style capabilities as we've nine totally different sort of RAFRamps forklift ramp with 15 different accessories. We have a tendency to manufacture ramp in keeping with your demand and which may be useful for your company. E) Physical Load Test of Ramp –

We are the only company to physically load test every ramp before delivery. All our ramps have One Year Warranty. We have customers who have been using the ramps for more than 5 years which is testament to the quality we provide Are you running a small company or a large-scale enterprise, rolling containers can make your business operations much smoother. Did you know that roll container, also called warehouse trolley, roll containers or roll cages for warehouse cage storage ? It’s a kind container equipment with four wheels used to transport and stock. It’s usually used in logistics distribution of large supermarkets and the logistics turnover between factory or laundry processes. Roll container products are widely used in almost all kinds of industries because of the convenience it provides when it comes to the transportation of different goods and services. No wonder roll containers are if so much of use and benefits. So, let us check out some of these major benefits associated with these containers. A) Durable - Roll Cages are particularly long lasting for coping with and wearing heavy gadgets. It offers safety from ability harm and additionally continues the products and merchandise saved safely. In addition, those bins are bendy sufficient to deal with distinct styles of jobs. That’s why curler bins are really well worth buying. B) Safety - These cages also are referred to as rolling protection cage in which they absolutely offer protection and protection to the gadgets stored interior it without a damage to them and are broadly used for distinct purposes. Also, those roll bins are with nesting functions which can be secure to paintings with in which the employees can without difficulty take care of it with entire protection. No wonder, those roll bins, metallic garage cage and cages are choosing up steam everywhere in the world. C) Easy to Use - These roll bins are very green in operating and really clean to apply. It offers guarantee of protection and reliability to the employees in fee all through the procedure of transportation. It has functions on excessive mobility and robust structure. D) Availability and Affordability - These roll containers are without difficulty to be had with inside the market, it has a extensive range with a purpose to supply comfort with the intention to without difficulty pick a appropriate field for a particular purpose. Also, those roll bins are affordable, so one does now no longer ought to spend a massive quantity and get the most advantage out of them. These bins are area savers while now no longer in use it may offer protection to anything These are the advantages of the use of those roll bins for which one must actually use. These are to be had, clean to apply and take care of, and are proof against harm the gadgets. So, begin rolling your gadgets throughout with those roll bins and get the advantages related to it.

If so, it’s time to contemplate investing in scissor lift tables. A scissor lift table may be a machine that's accustomed bring the load to a more ergonomic position, therefore increasing both the security and therefore the efficiency of your workday. These tables reduce the necessity for constant and repetitive bending, reaching, and lifting that may all be very taxing on the body. A scissor lift will help relieve your workers from back-breaking work and also make sure that your goods don’t get damaged. But, picking out the correct scissor lift table for your business isn’t always easy. There are an amazing amount of choices, and selecting a table which will best suit the requirements of your business may be a frightening task. 1. Intended Use Above all else, a scissor lift table should be selected supported its intended use. the utilization will help determine the capacity of the lift, the style, and any extra features which may be needed. Before you begin shopping, it’s important to look at and analyze your needs so you'll be able to work out the precise intended use for it. Make a listing of your needs and also the results you expect from the lift, so use this to guide you for other considerations. 2. Mobility Decide whether your are going use the scissor lift table during a fixed location or if it must be mobile. Things to stay in mind include: Assembly and production lines would require one that may be set in a very fixed location, whereas construction and maintenance work would require one that's mobile. If you would like it to be mobile, you’ll want to seem into lift tables that may be powered by battery or gas, as some spots might not have electricity available. 3. Load Another factor you need to take into consideration is the workload you need the lift to hold. Typically, a lift with more capacity is going to be more expensive. Therefore, if you have large loads that need to be moved, budget options may not be available to you. 4. Safety Features Safety is probably the foremost important consideration when buying a scissor lift table. the security of you and your employees should be of utmost priority. When buying a lift, safety features like lanyards, emergency buttons, and safety bars should all be taken into consideration. These safety features et al can help decrease accidents, which can increase efficiency and save your business time and money. 5. Height

There are two aspects with regard to height that require to be considered when buying a lift: First, you wish to think about the utmost height of the hundreds you wish to move. Lifts may be wont to move loads to some of this height with none issue. You also have to consider the peak of the lift when it’s collapsed, because it may have to be able to fit through a doorway or another shorter structure  Roll cages are widely used in warehouses. Transportation and goods management becomes quite easy and effective with them. These cages allow to easily move goods from one place to another inside and outside the warehouse premises. Introduction of different varieties and types in these containers have further given warehouse better and suitable options to choose from. These rolling containers and cages have wide applications in many industries. It might be the automobile industry, recycling industry or paper industry. All of these make use of high-quality rolling cages. Here are the some tips from experts from Al Ameen Engineering to help you choose the perfect roll A) Know your Requirements – The first step in shopping an ideal warehouse roll cages is to recognize your requirements. Know what your warehouse requirements are and what assist do you want with the roll cages. Make the tick list of the objects and characteristics that a roll cage trolley can also additionally display, in addition to objects that ought to now no longer be displayed. This will now no longer handiest come up with a quick concept of the cage trolley you want with inside the warehouse however additionally save you you from shopping for any form of cages or trolleys that doesn't meet your requirements. B) Recognize the cage according the same content – Now, as soon as you've got written down your necessities that the subsequent component you want to pick out the cages that fulfill your necessities. There are quantity of dealers and producers who promote numerous roll cages and warehouse trolleys. You will discover the suitable cage on your warehouse in those shops however ensure that the producer or supplier knows and recognize your necessities. Never purchase a roll cage that does not meet your necessities and proves useful to you. All cages trolleys are excellent, however you want to pick out the only that makes your warehouse phenomenal. That’s wherein the distinction is that enables you discover the suitable warehouse roll cages. C)Take the size of the cages into consideration – When buying warehouse roll cages, the scale of the cages have to do not forget now no longer simplest the scale of the products however additionally the scale of the warehouse channels. Only while those elements are do not forget collectively then simplest the cages maximize its overall performance and improves it paintings efficiency. D) Identify the site to be used – Its vital to become aware of in which you'll use the cages for eg – Workshop, warehouse, or supermarkets. In the workshop the possibility of guide trolleys is especially higher. It is mild and hard work saving to push and feature brakes. If is utilized in warehouse, from time to time the hassle of the fork need to be considered. Sometimes the products at the roll cages are transported without delay via way of means of forklift. E) Take the cost issues into consideration – Before creating a purchase, we should take the fee into consideration. We ought to understand how a good deal you may spend in a roll cages and what are the returns and income your warehouse will get. This whole evaluation and assessment will assist you to locate the appropriate roll cages for you warehouse which proves to be useful and fee-effective. Therefore, make certain which you take fee into concern. F) Improve Efficiency – In the warehouse or grocery store operations, earnings margins are calculated on the idea of the most items and merchandise saved in smallest to be had area. Therefore, it's miles essential to enhance performance with powerful area utilization.

In addition, you could ask you provider for numerous warranties they are able to provide, that can make deal worthwhile for you. All the steps will assist you discover the correct roll cages that is price powerful and useful on your warehouse. Most importantly, the roll cages proves ideal on your requirements. |

Archives

March 2024

Categories

All

|

|

We are a 30 year boutique fabrication company located in Dubai with passion in making great industrial equipment. Our mission is to create high quality products which would save time, money and increase productivity.

|

Quick Links |

Services |

Products |

SUBsCRIBE HERESubscribe to our mailing list to get the updates to your email inbox!

|

RSS Feed

RSS Feed