|

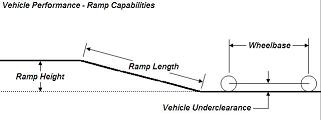

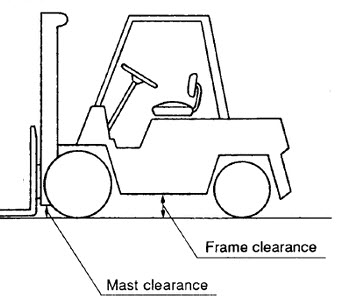

At Al Ameen Engineering we have accumulated lots of experience in fabricating the right kind of forklift ramp for your needs which will not only increase productivity and speed of loading/unloading but also ensures safety of your workers which boosts worker morale thus increasing output and reducing costs. This post is the second of the "how to choose forklift ramp" series with the focus on your forklift. This post would be beneficial if you are planning to buy a new forklift or if you already have a forklift, this will help to customize the ramp. Here are 4 things to look for in forklift or mention them to forklift manufacturer. i, Electric/Gasoline/Diesel Forklift - There are different types of forklifts required for different purposes. For Food, Paper and other manufacturing industries electric forklifts are preferred as they would not pollute or contaminate the goods. The gasoline/diesel on other hand are used mainly outdoors where there is free flow of air and usually carry heavier goods or cargoes compared to electric ones. It is imperative that you mention what kind of forklift you have. ii, Gradeability/Max. Gradeability - Gradeability is a the highest grade a vehicle can ascend while maintaining a particular speed is termed that vehicle's "gradeability" (source: wikipedia). It is imperative to know this as it determines what maximum angle/grade a forklift can climb and maintain constant speed. Gradeabilty of electric forklifts are usually lower compared to gas forklifts which shows electric forklifts requires more distance or slope to climb to a height. Max gradeability shows what is the maximum angle a forklift can climb without maintaining constant speed. This is important information ramp manufacturers need to make custom ramps with easy slope to climb. Providing wrong grade information can cause problems while climbing so make sure right information is provided. iii, Wheel Base - It is the distance between the center of front and rear wheels. If the wheels are closer one can steer easily in small radius, if it is farther one has to take longer to steer around and needs more slope distance to cover and enter the container or level off area. Shorter wheelbase can climb on steep slope. iv, Vehicle underclearance - It is distance between the ground and the lowermost part of the forklift. More distance it has the forklift can climb steep slopes. Diesel and Petrol forklifts normally has higher underclearances compared to electric forklifts. There are two things one has to look for undeclerances - mast underclearance and frame underclearance. Provide the underclearances of the forklift when they are fully loaded with the maximum weight it can carry. Check out the manufacturer's specification sheet for more information on this and make sure you provide max load clearance. Note that if your forklift has inflatable rubber tires then it sinks more when loaded as when it has solid rubber tires. v, L-Shaped Loading - Do you need L-shaped Loading? (Click here)

0 Comments

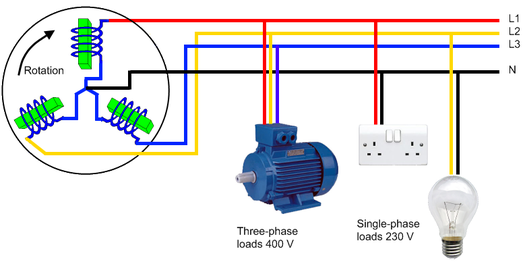

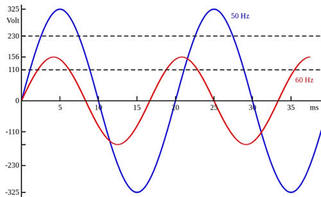

Did you plan to fabricate a new or modify existing forklift ramp? If you are installing hydraulic landing jacks then read this post as it can save you lots of money before you make mistake in buying one. Though this guide is not comprehensive it is good enough for you to understand your needs before welding a hydraulic cylinder jack to your fabricated ramp. So what do you have to know? a, Single Phase or Three Phase Do you have single or three phase electric installation in the place where you will place your yard ramp? If you are ordering electric powered hydraulic systems then you have to read this section. Single phase powers most of the non-commercial and industrial outlets. Triple phase is used mainly in industrial firms which require high powered output on some machines. Ask your engineers or technicians and know this before hand before ordering custom steel fabricated ramps. b, Frequency In UAE the motors with 50Hz are used whereas in neighboring Saudi Arabia 60Hz is used. Ask the frequency of the pump motors of your power pack to know what you are getting. c, Manual Lever or Control Panel

Manually lever is same as mechanical which has almost all the components same as the electric powered only difference is control panel unit. Lever unit costs about -$1000 to $1500 less (Dhs 3000-4000) and advantage of lever powered is that it can be used anywhere as it is not electric powered. Electric powered system is powered and you have to know if it is powered by single or triple phase. In the control panel other than up and down there should be optional emergency button. After you have invested money on forklift ramp, it is now time to choose the best accessories to make best use of our ramp. We at Al Ameen Steel Fabrication Engineering, Dubai, U.A.E have had lots of experience installing ramps. From our long experience, we have an idea on what it takes to make full use of forklift ramp. Here are some of the safety features you will have to consider before buying a ramp : - a, We provide high curbs to prevent run-offs compared to tubing which can be easily knocked loose. b, Safety chains are provided to secure ramp to dock or trailer. c, Robust design for strength and easy moving around. When constructing a forklift ramp you must mention the maximum tonnage the ramp must take. d, High quality galvanized grating sheet that would prevent dust and sand from accumulating and prevent rust and any slippery.

Al Ameen Engineering is one of the leading manufacturers of light and heavy duty forklift ramps located in Dubai, UAE. According to our experience,selecting a forklift ramp can be (also known as loading ramps, portable ramps, mobile ramps, loading dock ramp, portable loading ramp, portable loading dock, mobile loading dock, mobile dock ramps, mobile yard ramps, loading docks, yard ramps) quite challenging if you do not know for what purpose you would use one for. We have had requests from many logistics, transportation and oilfield service companies to work on custom ramp only later asking us to modify it later. There are many factors to look into before choosing a mobile ramp which would suit your budget and needs. Here are some of them you have to check before deciding to buy one. Purpose - What is the main purpose of using your ramp? Do you want to load your containers with forklift? Transport vehicles? Heavy Construction equipments? Different requirements have different designs and build when comes to making one. So determine the purpose of buying your ramp then head to specifications.

|

Archives

March 2024

Categories

All

|

|

We are a 30 year boutique fabrication company located in Dubai with passion in making great industrial equipment. Our mission is to create high quality products which would save time, money and increase productivity.

|

Quick Links |

Services |

Products |

SUBsCRIBE HERESubscribe to our mailing list to get the updates to your email inbox!

|

RSS Feed

RSS Feed